- Limitations of Standard Solids Control and the Need for a Booster System

- Inside the VacEvap Solids Control System: Design Built for Higher Recovery

- Flow Path Breakdown: How the Booster Fits Into the Solids Control Chain (with Market & Waste-Management Context)

- Pump Integration: How the VacEvap Works With Solids Control Booster Pumps and Slurry Booster Pump Systems

- Industrial Applications Where VacEvap Improves Total System Throughput

- Why Choose VacEvap and Slurry Separation for Solids Control Upgrades

- Practical Considerations for Deployment and Maintenance

- Wrapping up: A More Efficient Approach to Final-Stage Dewatering

Operators in drilling, mining, tunneling, and industrial slurry handling increasingly work under conditions where conventional solids control is no longer sufficient. Higher material throughput, tighter environmental expectations, and rising waste-management costs demand more efficient separation than what standard screening and hydrocyclone stages can deliver. Traditional systems remove bulk solids, but they often leave significant moisture in the cuttings stream. This results in heavier waste, higher disposal volumes, and added load on downstream pumps and equipment.

Slurry Separation focuses on solving these operational challenges with practical and reliable equipment built for real project environments. The company develops separation technologies that reduce fluid loss, improve solids dryness, and streamline handling across a wide range of slurry applications.

This blog explains how the VacEvap enhances dewatering performance beyond traditional methods. It outlines how the system’s design, flow mechanism, and compatibility with solids control booster pumps and slurry booster pump integration create a more efficient and predictable solids management process for industrial operators.

Limitations of Standard Solids Control and the Need for a Booster System

Standard solids control relies on screens, hydrocyclones, and centrifuges to remove suspended solids from drilling mud or process slurry. While these stages effectively separate larger and fine particles, they often leave excess moisture in the cuttings. This residual fluid becomes a recurring operational challenge because it increases waste volume, raises handling effort, and drives up transport and disposal costs. In high-volume drilling or mining programs, even a small percentage of retained fluid can significantly impact overall project efficiency.

Another limitation is the performance drop that occurs when slurry properties change. Variations in solids loading, viscosity, or particle size distribution can reduce screen efficiency or overwhelm downstream equipment. When separation stages operate at their limits, operators experience increased pump wear, shortened screen life, and inconsistent solids dryness. These limitations highlight the need for an additional dewatering step to stabilise the output, regardless of changing site conditions.

A solids control booster pump or a dedicated vacuum-based unit offers a practical way to overcome these gaps. By applying controlled suction after the primary separation stages, a booster system can remove fluid that standard equipment cannot access. This improves solids dryness, reduces waste volume, and increases the overall yield of recovered fluid. For Slurry Separation customers, this aligns with the company’s focus on delivering simple, efficient systems that support cleaner, more manageable operations across drilling, mining, tunnelling, and slurry-intensive industries.

Inside the VacEvap Solids Control System: Design Built for Higher Recovery

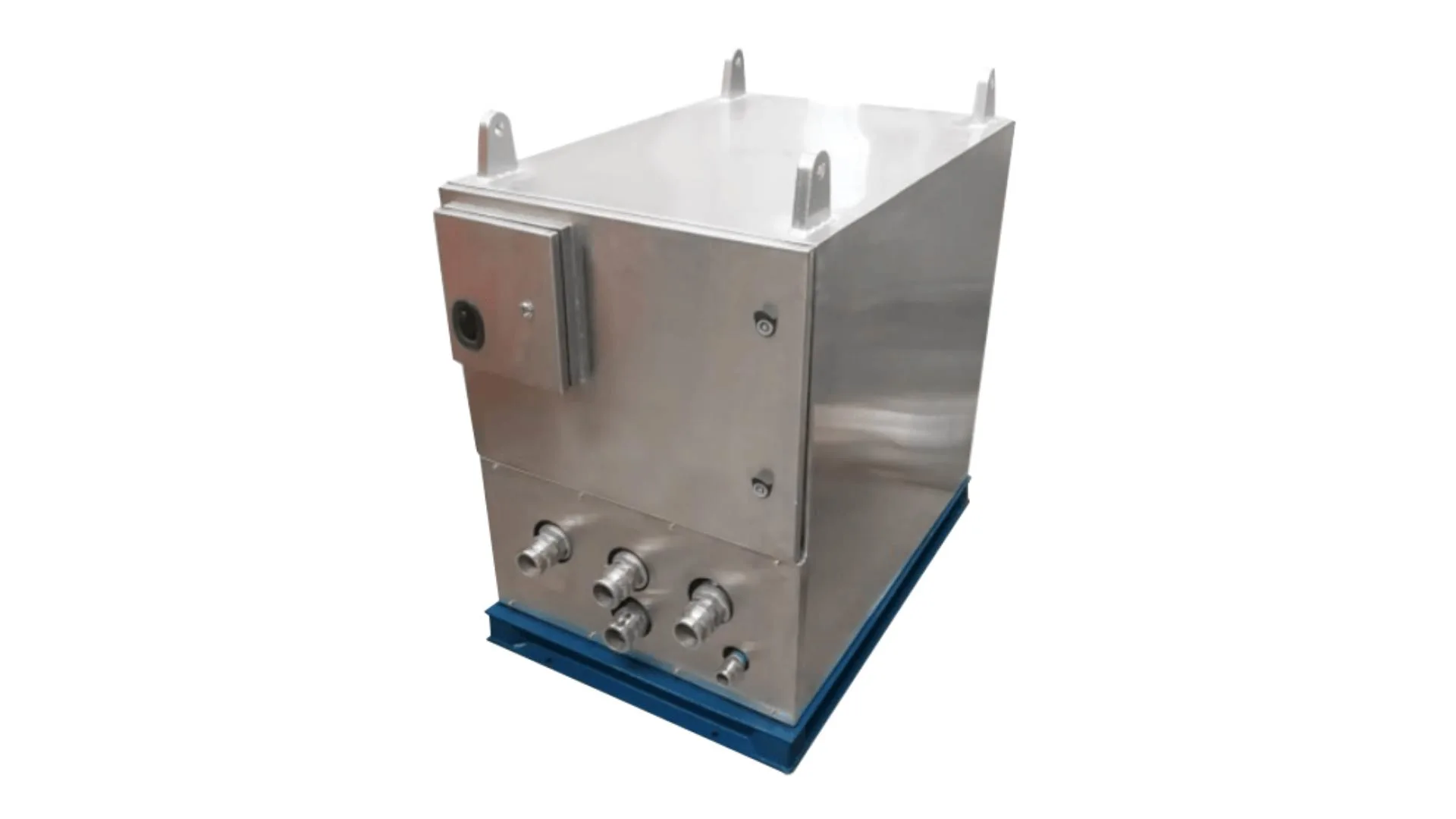

The VacEvap is engineered as a compact, high-efficiency dewatering unit that enhances the final stage of solids separation. Its design focuses on removing the fluid that conventional screening cannot capture, thereby improving cuttings dryness and reducing overall waste volume. The system is built for operators who need predictable results in demanding conditions without adding complexity to their workflow.

Compact mechanical structure created for restricted job sites

The VacEvap is designed with a small footprint and a durable frame that fits easily into crowded drilling pads, mining plants, and tunnelling sites. Its dimensions and weight allow simple placement near existing separators, and its build quality supports continuous operation. This aligns with Slurry Separation’s approach of offering equipment that is easy to position, easy to maintain, and capable of performing reliably in field environments where space and accessibility are often limited.

Controlled vacuum operation that improves final-stage dewatering

The system uses compressed air to generate a stable vacuum that extracts retained fluid from cuttings after they pass through the last screen. Operators can adjust suction and discharge timing to match the slurry characteristics or job-specific requirements. The VacEvap can be connected to up to three slurry separators using a single air supply, which makes it practical for multi-line operations without requiring additional infrastructure. This controlled VacEvap enables recovery of an additional 2000 to 3000 liters of fluid per day when used with a single shaker.

Performance outcomes that differentiate the VacEvap solids control system

By applying targeted vacuum extraction, the VacEvap reduces cuttings’ moisture content by approximately 30-50%. This improvement enhances downstream handling, lowers disposal effort, and supports cleaner operations. The reduction in retained fluid also decreases strain on screens and pumps, helping extend their service life. For operators looking to optimise both performance and operating costs, the VacEvap delivers measurable improvements without requiring changes to the primary separation setup.

This section of the system demonstrates how Slurry Separation designs equipment to support real-world field performance. The VacEvap’s technical structure and operating principles reflect the company’s focus on reliable, straightforward solutions that deliver immediate value when integrated into an existing solids control line.

Flow Path Breakdown: How the Booster Fits Into the Solids Control Chain (with Market & Waste-Management Context)

Typical Process Flow with VacEvap Integration

- First, slurry or drilling mud is processed via primary separation components, for example, shakers (to remove coarse cuttings), followed by hydrocyclones, desanders/desilters, or centrifuges to separate finer solids.

- After the final mechanical separation stage, the relatively wet cuttings or solid-laden slurry discharge enter the dewatering booster stage. That is where the VacEvap Solids Control Booster is activated. Using a vacuum induced by compressed air, VacEvap extracts residual fluid remaining in cuttings or slurry.

- The recovered fluid is routed back into the system or collected for reuse/disposal. The dewatered solids, now significantly drier, are easier to handle, transport, dispose of, or further process.

- This final dewatering stage does not replace primary separation; instead, it supplements the existing workflow, providing operators with improved moisture reduction, reduced waste volume, and better solids handling.

This process flow helps visualize where the VacEvap solids control system sits in the separation line and how it bridges the gap between conventional separation and final waste handling or disposal.

Why this Matters: Industry Waste Loads and Market Driving Factors

- The global market for drilling waste management reached approximately USD 5.43 billion in 2023.

- According to industry reports, the demand for solids-control and waste-management services continues to rise, driven by stricter environmental regulations, increasing drilling and mining activities, and the need for efficient waste handling.

- Within waste generated by drilling and related operations, cuttings and solids typically account for a significant portion of the waste stream. Effective reduction of fluid in cuttings via dewatering boosters, such as VacEvap solids control booster pumps, therefore plays a major role in reducing overall disposal volumes and costs. Research shows that depending on geology, well depth, and drilling fluid, a single well may generate several thousand barrels of drilling waste.

By integrating a vacuum-based booster after traditional separation stages, operators can directly address a major challenge in waste handling: reducing liquid waste in cuttings. This helps lower downstream disposal costs, minimize environmental impact, and improve efficiency, making the entire solids control and waste-management chain more sustainable and cost-effective.

Pump Integration: How the VacEvap Works With Solids Control Booster Pumps and Slurry Booster Pump Systems

Pump integration is a critical part of ensuring that the VacEvap performs consistently across drilling, mining, tunneling, and industrial slurry workflows. Since the VacEvap operates as a final-stage dewatering unit, it must connect smoothly with both the upstream separation equipment and the supporting pump circuits. This section explains the key technical points operators must understand before installing the system on an active site.

Compressed air supply requirements for stable vacuum generation

The VacEvap solids control system relies on a compressed air source to create a controlled vacuum. For reliable operation, the system requires an air supply of 100 to 150 PSI and an airflow capacity of approximately 280 CFM. This allows the unit to maintain consistent suction strength even when slurry properties fluctuate. Because many drilling and mining sites already use compressed air for rig operations, integrating the VacEvap typically does not require new infrastructure.

Connection points and hose compatibility

The VacEvap solids control system is designed with multiple 2-inch suction inlets and a single 2-inch discharge outlet. These standardized ports simplify the mechanical connection to solids control booster pumps and slurry transfer systems. Operators can route suction hoses directly from the final shaker screen or separator, while the discharge hose returns recovered fluid to a designated holding tank or fluid system. The straightforward port design supports quick setup and reduces the likelihood of compatibility issues during installation.

Maintaining performance within existing solids control pump systems

Since the VacEvap solids control system operates after primary separation equipment, it does not disrupt the performance of vertical slurry pumps, centrifugal mud pumps, or hydrocyclone feed pumps. Instead, it complements them by reducing fluid retention in cuttings. Lower moisture content means fewer blockages, more stable flow rates, and less strain on downstream pumping systems. Slurry Separation designs its equipment to ensure that adding a vacuum booster does not require recalibrating the existing pump line or redesigning the solids control layout.

Practical advantages for multi-line operations

The VacEvap solids control system can connect to up to three separators using a single air source. This feature supports multi-line drilling or slurry-processing setups commonly used in tunneling, mining, dewatering plants, and horizontal drilling projects. For operators managing multiple lines simultaneously, the ability to integrate a slurry booster pump with several separators simplifies the system architecture and improves overall efficiency without expanding the equipment footprint.

Through these integration features, the VacEvap solids control system provides both operational and economic advantages. It enhances the performance of solids control booster pumps, improves slurry booster pump integration, and supports more predictable fluid recovery across diverse industrial conditions.

Industrial Applications Where VacEvap Improves Total System Throughput

The VacEvap is built for industries where slurry processing and waste management directly affect operational cost, regulatory compliance, and project timelines. By reducing moisture content in cuttings and recovering additional fluid at the final separation stage, the VacEvap solids control system supports more stable performance across a wide range of industrial environments. This section outlines where operators gain the most value from integrating the system into their solids control workflow.

Oil and gas drilling waste management

Drilling operations generate large volumes of cuttings that often carry significant retained fluid after passing through primary separation equipment. The VacEvap solids control system helps operators reduce retained fluid by 30 to 50 percent, lowering transport weight, reducing waste-handling costs, and supporting cleaner drilling sites. With the ability to recover up to 2000 to 3000 liters of additional fluid per day when paired with a single shaker, the system gives drilling teams a practical tool to improve both efficiency and environmental performance.

Mining and mineral processing

Mining slurry often contains a mix of abrasive solids and fine particles that are difficult to dewater with cyclones or screens alone. The VacEvap solids control system adds a dewatering step that stabilises solids dryness, improving material flow and reducing the load on downstream pumps and conveyors. This supports more predictable plant operations and lowers moisture-driven penalties in transport or tailings handling.

Tunneling, HDD, and microtunneling slurry handling

Horizontal directional drilling and tunneling projects require continuous slurry removal to maintain safe working conditions. High moisture content in cuttings increases disposal volumes and complicates site logistics. Integrating the VacEvap solids control system provides final-stage moisture reduction, making cuttings lighter and easier to move, and supports faster turnaround in confined urban or underground project environments.

Dredging and high-volume slurry transfer

In dredging, large volumes of silt and sediment must be processed quickly. Moisture-heavy material increases transport requirements and slows production. The VacEvap solids control system lowers fluid content before discharge, which supports smoother loading, more consistent material transfer, and reduced dependence on additional booster pumping stages.

Across these sectors, operators benefit from slurry booster pump integration because it fits directly into existing solids control setups without requiring a redesign of the entire system. Slurry Separation positions the VacEvap as a practical, field-ready upgrade that improves throughput, lowers waste volumes, and strengthens overall solids control performance in demanding industrial environments.

Why Choose VacEvap and Slurry Separation for Solids Control Upgrades

Selecting the right solids control enhancement is not only a technical decision but also an operational one. The VacEvap solids control system is designed to deliver measurable improvements in moisture reduction and fluid recovery while maintaining compatibility with existing separators, pumps, and site utilities. Slurry Separation positions this system as a practical upgrade that integrates easily into real-world industrial environments without adding operational complexity.

A system engineered for immediate field value

The VacEvap solids control system is built to solve a specific problem in solids handling: excess fluid that remains even after efficient screening and cyclone separation. By creating controlled vacuum conditions, the system consistently improves solids dryness by approximately 30-50%. For operators handling large slurry volumes, this improvement translates directly into reduced disposal costs, easier material movement, and fewer delays caused by oversaturated waste.

Compatible with the company’s broader equipment ecosystem

Slurry Separation designs its products so they work together without modification. The VacEvap can connect up to three separators to a single air source, allowing operators to scale capacity without purchasing additional infrastructure. This compatibility supports both single-line operations and multi-line industrial setups, making the system suitable for drilling rigs, mining plants, tunneling slurry loops, and dredging operations.

Built to simplify operations, not complicate them

One of the defining strengths of Slurry Separation equipment is its focus on simple, reliable operation. The VacEvap follows this principle. It uses a straightforward vacuum cycle with adjustable suction and discharge timing, allowing operators to tune performance without advanced technical intervention. This reliability reduces downtime and helps maintain consistent output even under variable slurry conditions.

Supported by a company focused on practical, high-value solutions

Slurry Separation provides solids control booster pump systems that prioritise efficiency, durability, and ease of deployment. The VacEvap solids control system reflects this approach by offering a compact footprint, strong performance, and low operational demands. For clients evaluating solids control upgrades, the company’s equipment and support services offer a complete package that strengthens overall system throughput and lowers long-term operating costs.

Through these advantages, the solids control booster pump becomes more than an add-on unit. It becomes a major part of a streamlined solids management strategy that enhances operational efficiency and supports better control of waste, fluid recovery, and equipment performance across industries.

Practical Considerations for Deployment and Maintenance

The VacEvap is built for simple field integration, but a few practical checks help ensure consistent performance.

Site and air supply readiness

Confirm that the site has a stable compressed air source at 100-150 PSI and about 280 CFM. Position the unit close to the final separation stage to maintain a steady vacuum strength.

Straightforward hose setup

Use the system’s 2-inch suction inlets and 2-inch discharge outlet to connect directly to the final shaker or separator. Proper hose routing prevents flow restrictions and keeps suction stable.

Adjusting vacuum cycles

Operators should set suction and discharge timing based on slurry behaviour. A short observation period during startup helps identify the most efficient cycle for the site conditions.

Basic routine checks

Inspect hoses, fittings, and vacuum lines for leaks. Monitor dryness in cuttings and verify that the discharge line remains clear. The VacEvap’s simple structure supports quick field maintenance.

Alignment with waste-handling workflow

Drier solids reduce transport weight and disposal volume, allowing operators to adjust logistics or storage methods accordingly.

This concise approach keeps the slurry booster pump integration easy to deploy and maintain while ensuring reliable performance across drilling, mining, tunnelling, and industrial slurry applications.

Wrapping up: A More Efficient Approach to Final-Stage Dewatering

The VacEvap solids control system provides operators with a practical, measurable way to strengthen their solids control workflow. By removing additional fluid after traditional separation stages, the system improves cuttings dryness, increases recovered fluid volume, and reduces waste handling effort. Its compact structure, adjustable vacuum cycle, and compatibility with multiple separators make it a simple upgrade that fits naturally into existing drilling, mining, tunnelling, and slurry processing operations.

For teams looking to improve throughput without redesigning their entire solids control line, the VacEvap offers a clear path to better efficiency and lower operating costs. Slurry Separation continues to focus on equipment that delivers reliable, field-ready performance, and the VacEvap reflects this commitment by providing operators with a dependable solution for final-stage dewatering challenges.