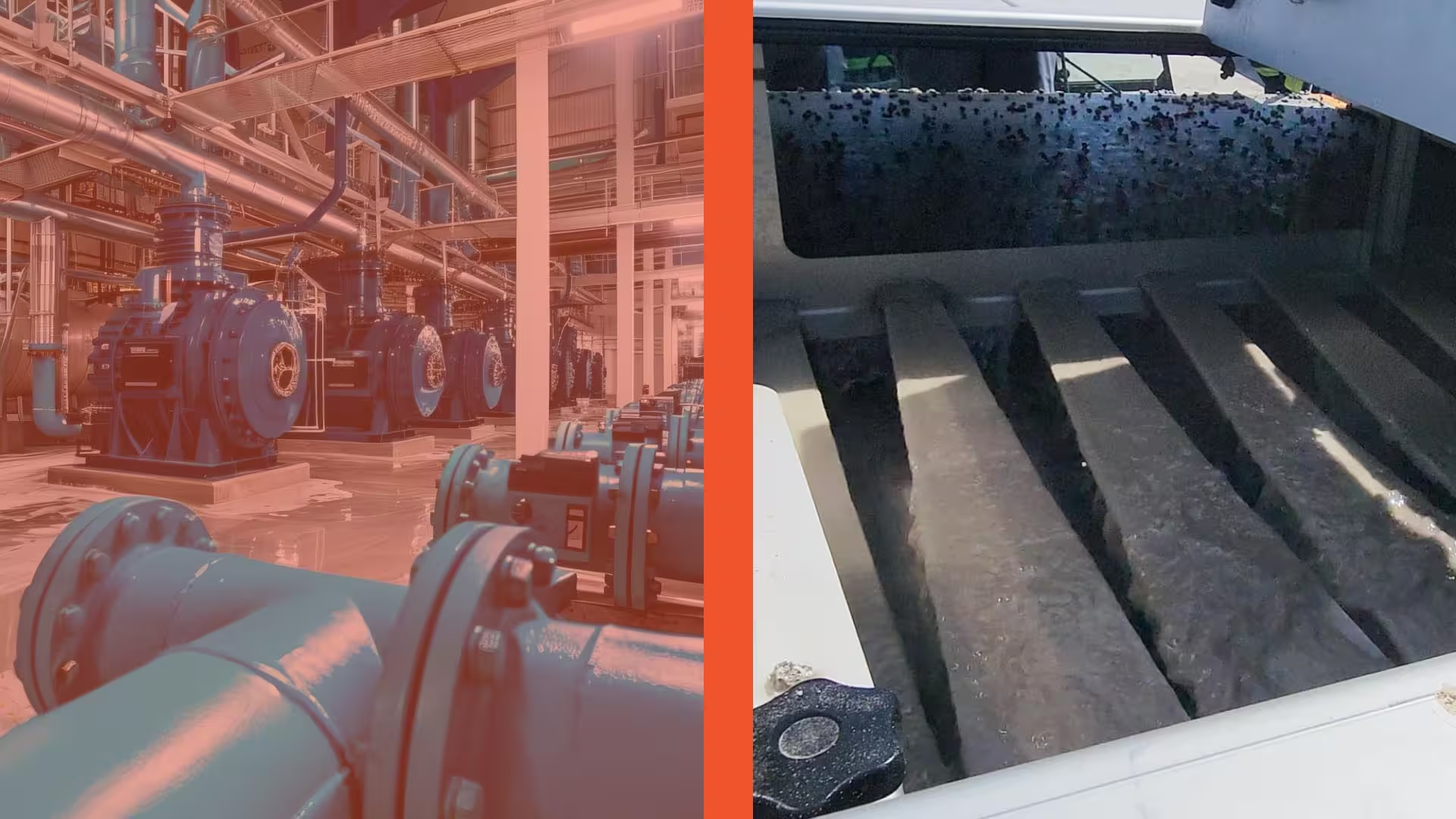

Solid separation is a critical process in many industrial settings, where the efficient removal of solids from liquids is essential for maintaining productivity and ensuring the quality of the final product. Solid separator equipment plays a vital role in industries such as wastewater treatment, food processing, and mining. The effectiveness of this solid separation equipment directly impacts operational efficiency, product quality, and overall costs.

Given the importance of solid separation, the selection of solid separator equipment must be focused on cost-effectiveness. Cost-effectiveness, in this context, doesn’t just mean opting for the cheapest equipment available. Instead, it involves evaluating the total cost of ownership, including factors such as energy efficiency, maintenance requirements, durability, and performance. This article explores the need for solid separator equipment, the key factors to consider when selecting cost-effective solid separation solutions, and the types of equipment available to meet industrial needs.

Understanding the Need for Solid Separator Equipment

Challenges of Solid-Liquid Separation

Solid-liquid separation is a complex process that presents several challenges across various industries. For instance, in wastewater treatment, the removal of solid particles from the effluent is crucial to meet regulatory standards and ensure environmental safety. In food processing, efficient separation is needed to maintain product quality and consistency, while in mining, separating solids from liquids is essential to recover valuable materials and reduce waste. Utilizing a solid waste separator is key in these processes, as it ensures that the separation is thorough and efficient, minimizing the loss of valuable materials.

These challenges often include handling a wide range of particle sizes, managing high flow rates, and dealing with abrasive or corrosive materials. The efficiency of the solid waste separator and other solid separation equipment can significantly affect the overall operation, leading to higher costs if not managed properly.

Impact of Inefficient Separation

Inefficient solid-liquid separation can result in several adverse outcomes, including increased operational costs, equipment downtime, and even environmental violations. For example, inadequate separation in wastewater treatment can lead to regulatory penalties and damage to the environment. In industries like mining, poor separation can cause the loss of valuable materials, reducing the profitability of the operation. Additionally, inefficient separation processes often require more frequent maintenance and higher energy consumption, further driving up costs.

Key Factors in Selecting Cost-Effective Solid Separator Equipment

Efficiency and Performance

When selecting solid separator equipment, efficiency and performance should be top priorities. Equipment that maximizes separation efficiency ensures that most solids are removed from the liquid, reducing the need for secondary processes and minimizing waste. Factors that influence performance include the size and nature of the particles being separated, the flow rate of the liquid, and the material composition of both the solids and the solid separation equipment. High-performance equipment typically offers better long-term value, even if the initial investment is higher.

Durability and Longevity

Durability is another critical factor that impacts the cost-effectiveness of solid separator equipment. Equipment made from high-quality materials designed to withstand harsh industrial environments will have a longer lifespan and require fewer repairs or replacements. This reduces long-term operational costs and minimizes downtime, which can be costly in industries where continuous operation is essential. Investing in durable solid separation solutions is a cost-effective strategy that pays off over time.

Energy Consumption

Energy efficiency is increasingly important in industrial operations, both for cost savings and environmental considerations. Solid separator equipment that consumes less energy while maintaining high performance can significantly reduce operational costs. For example, modern centrifugal separators and decanter centrifuges are designed with energy-efficient motors and optimized flow designs that minimize energy consumption. Selecting energy-efficient solid separation equipment is a crucial component of a cost-effective strategy.

Maintenance and Operational Costs

Maintenance and operational costs are ongoing expenses that must be considered when selecting solid separator equipment. Equipment that is easy to maintain and has lower operational costs will contribute to overall cost-effectiveness. User-friendly designs, readily available spare parts, and equipment that requires minimal intervention can reduce maintenance time and costs. Additionally, choosing equipment that has a strong support network or manufacturer warranty can further enhance cost savings.

Types of Cost-Effective Solid Separator Equipment

Centrifugal Separators

Centrifugal separators are widely used in various industries due to their ability to separate solids from liquids efficiently at high speeds. They use centrifugal force to accelerate the separation process, making them ideal for applications where quick and efficient separation is required. Although they may have a higher initial cost, their high efficiency and low maintenance requirements make them cost-effective in the long run.

Vibrating Screens

Vibrating screens are another cost-effective solution for solid separation, particularly in industries such as mining and food processing. These screens use vibration to move solids across a mesh, allowing liquids to pass through while retaining the solids. They are relatively simple in design, easy to maintain, and suitable for handling large volumes, making them an economical choice for many applications.

Decanter Centrifuges

Decanter centrifuges are highly efficient in separating solids from liquids, especially in applications where the solids are dense, or the fluid is highly viscous. These centrifuges operate continuously and can handle large volumes, making them ideal for industrial applications. While they may require a significant upfront investment, their ability to handle challenging separation tasks and reduce waste makes them a cost-effective solid waste separator option over time.

Filter Presses

Filter presses are commonly used in industries such as wastewater treatment and food processing. They work by applying pressure to force liquids through a filter medium, leaving the solids behind. Filter presses are highly effective in achieving a high degree of separation and are particularly useful for applications where the solids need to be dried. Their low operational costs and minimal energy consumption contribute to their cost-effectiveness as a solid separator solution.

Tips for Maximizing Cost-Effectiveness

Regular Maintenance Practices

Regular maintenance is essential to ensure that solid separator equipment operates efficiently and has a long lifespan. Implementing a maintenance schedule that includes routine inspections, cleaning, and part replacements can prevent costly breakdowns and extend the life of the solid separation equipment.

Selecting the Right Equipment for Specific Needs

Choosing the right equipment for your operation’s specific needs is crucial for cost-effectiveness. Assess the requirements of your separation process, including the type of solids, liquid properties, and desired level of separation, to select solid separation solutions that offer the best balance of performance and cost.

Energy Efficiency Considerations

Reducing energy consumption is a key aspect of maximizing cost-effectiveness. Consider investing in energy-efficient solid separator equipment and implementing operational practices that reduce energy usage, such as optimizing flow rates and using automated control systems.

Conclusion

Selecting cost-effective solid separator equipment is essential for maintaining operational efficiency and minimizing costs in industrial settings. By focusing on factors such as efficiency, durability, energy consumption, and maintenance, businesses can choose solid separation solutions that offer the best value over time. Investing in high-quality, durable, and energy-efficient solid separation equipment, including a solid waste separator, may require a higher initial investment. Still, it pays off in the long run through reduced operational costs and improved performance.