- Understand the Operating Conditions of Your Slurry Separation Equipment

- Establish a Routine Inspection and Monitoring Schedule

- Lubrication, Seal, and Bearing Maintenance

- Cleaning and Flushing Procedures

- Replacement and Calibration of Critical Components

- Training Operators and Maintenance Teams

- Leverage Remote Monitoring and Predictive Technologies

- Partner with Your Equipment Manufacturer

- Protecting Your Investment with Smart Maintenance

Slurry separation equipment plays a crucial role in high-demand industries, including mining, oil and gas, municipal wastewater treatment, naval operations, and industrial processing. These advanced systems are designed to manage large volumes of abrasive and corrosive mixtures by effectively separating solids from liquids. This not only streamlines downstream processes but also ensures regulatory compliance, reduces environmental risks, and maintains steady operational flow.

In mission-critical environments, downtime is far more than an inconvenience; it can be extremely costly. A single failure in a slurry separator machine during operations like mine dewatering or municipal sludge treatment can lead to halted production, environmental penalties, emergency repair costs, and safety hazards. For companies operating with tight project schedules, these disruptions can severely impact profitability and project timelines.

Preventive maintenance is the most effective strategy to avoid such setbacks. By implementing consistent maintenance routines, businesses can extend the lifespan of their slurry separation equipment, enhance overall system efficiency, and minimize the likelihood of unexpected breakdowns. This approach not only yields improved ROI but also reduces the total cost of ownership, providing a solid financial foundation for your operations.

This guide empowers you with proven tips to maintain Solid-liquid separation machinery. It provides project managers, engineers, and procurement teams with actionable strategies to optimize system performance, whether for permanent installations or mobile units designed for challenging site conditions.

Understand the Operating Conditions of Your Slurry Separation Equipment

Before establishing a maintenance strategy, it’s essential to understand how your slurry separation equipment performs under your site’s unique conditions. This knowledge will keep you informed and prepared for any situation that may arise. While this equipment is designed for durability and flexibility, real-world performance is heavily influenced by operating variables, including slurry composition, pH, flow rate, temperature, and solids content.

- Flow Rate: When flow exceeds system design limits, it can overwhelm screens and membranes, leading to premature wear or clogging.

- Solids Concentration: High solids content places a greater demand on mechanical components and increases the frequency of required cleanouts.

- Abrasive or Corrosive Materials: Slurries containing metal fines, sand, or chemicals accelerate component wear, requiring corrosion-resistant materials and tighter maintenance schedules.

- Operating Pressure and Temperature: High pressure and extreme temperatures stress seals, gaskets, and structural elements, potentially leading to accelerated degradation if not addressed.

By aligning your slurry separator machine specifications with these factors, you can significantly reduce maintenance frequency and extend system longevity. In abrasive industrial settings, such as mining and mineral processing, upgrading to Solid-liquid separation machinery with wear-resistant linings or specialty alloys can make a measurable difference in performance and durability.

Understanding and anticipating the impact of your operating conditions is a cornerstone of smart maintenance and optimal use of slurry separation equipment.

Establish a Routine Inspection and Monitoring Schedule

Routine inspections are the foundation of effective preventive maintenance for slurry separation equipment. These inspections, which include both visual and data-driven components, enable operators to identify early signs of wear, misalignment, or clogging before they escalate into costly equipment failures or unplanned downtime.

Key inspection activities include:

- Visual Checks: Regularly examine screens, seals, housings, and pipe connections for signs of fatigue, corrosion, or deformation.

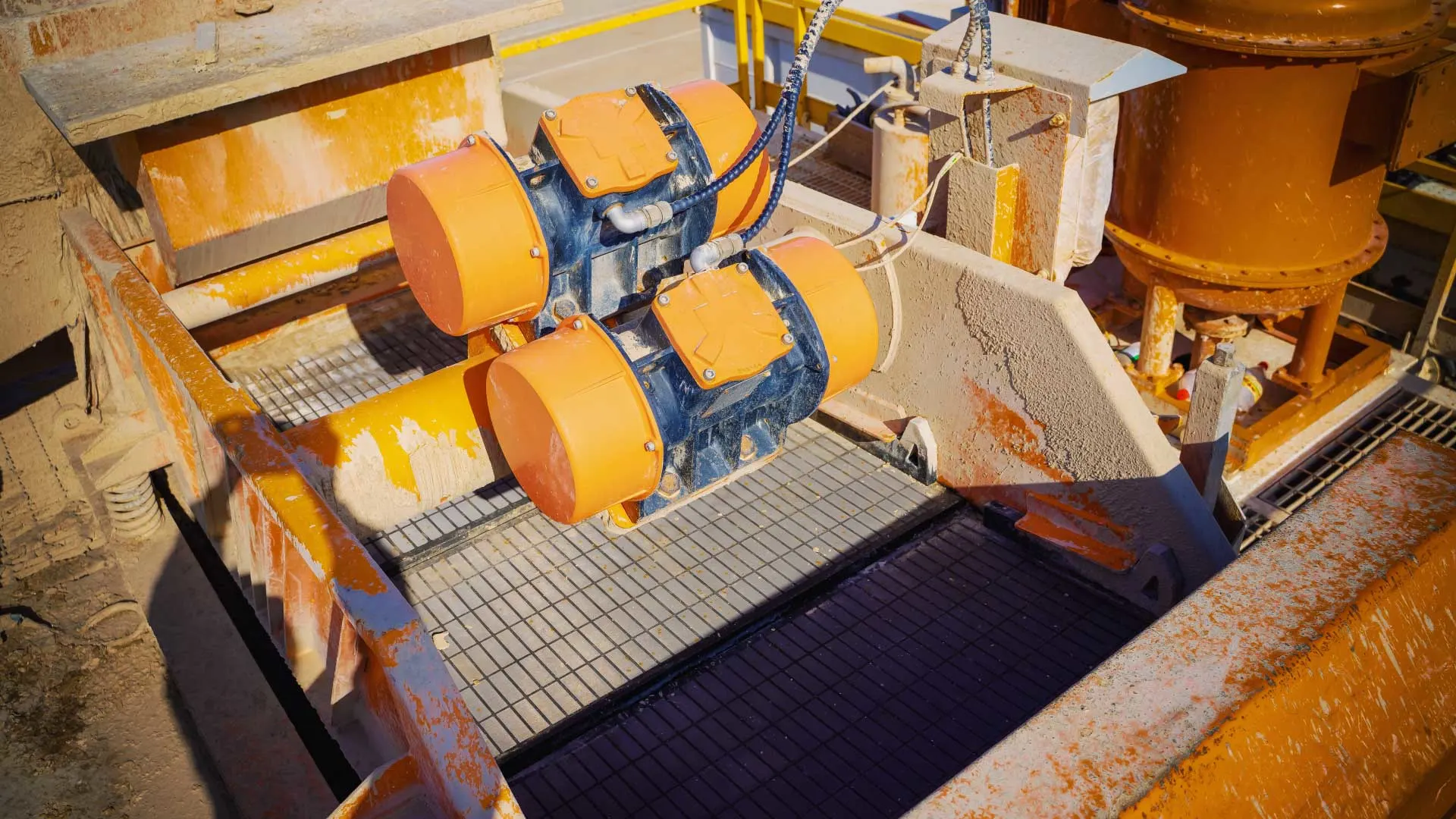

- Vibration and Noise Monitoring: Abnormal vibrations or unexpected noise may indicate issues with bearings, motor misalignment, or internal obstructions within the system.

- Sensor-Based Monitoring: Flow meters, solids sensors, and pressure gauges are essential for identifying declining system performance or detecting developing blockages.

Inspection frequency should be tailored to the application:

- Mining and mineral processing operations often demand daily or weekly inspections due to the abrasive nature of the slurry and high-duty cycles.

- Municipal and naval facilities handling more consistent or less abrasive loads may follow a bi-weekly or monthly schedule.

Consistent documentation of inspection data enables trend analysis, allowing maintenance teams to forecast problems and plan corrective actions during scheduled downtime. This minimizes emergency interventions and maximizes uptime.

Whether working with a mobile slurry separator machine or a stationary Solid-liquid separation machinery setup, routine inspections significantly extend the service life of your slurry separation equipment and protect your capital investment.

Lubrication, Seal, and Bearing Maintenance

Lubrication is one of the most fundamental, yet often overlooked, components of maintaining slurry separation equipment. Despite its simplicity, improper lubrication practices are a leading cause of equipment failure across industrial and municipal applications. From the use of incompatible lubricants to neglecting seal maintenance, even minor oversights can lead to significant downtime.

Best practices for lubrication and component care include:

- Use OEM-Specified Lubricants: These lubricants are engineered to meet the demands of the specific loads, speeds, and operating temperatures associated with slurry separation equipment.

- Regularly Monitor and Replace Seals: Seals are critical to protecting internal systems from slurry ingress. A worn or damaged seal can quickly lead to contamination, compromised separation performance, and internal corrosion.

- Check Motor and Bearing Alignment: Misaligned components generate excess heat and friction, dramatically shortening the lifespan of bearings and increasing the risk of failure.

When it comes to a slurry separator machine, lubrication plays a critical role in maintaining bearing integrity, especially in challenging environments with slurry splash, vibration, and fine solids. Improper practices here can quickly compromise even the most robust components.

Adhering to a scheduled lubrication and inspection routine is crucial for operators of Solid-liquid separation machinery. This practice significantly enhances reliability and extends the operational life of their slurry separation equipment investment.

Cleaning and Flushing Procedures

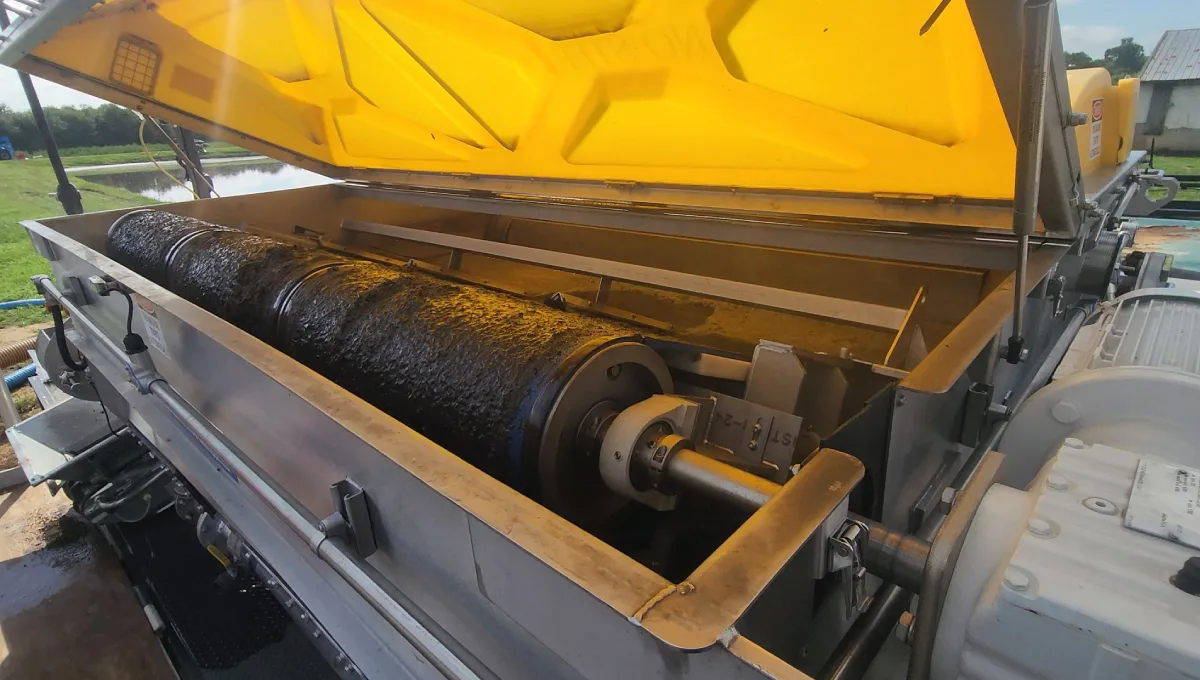

Residual buildup is a common and persistent threat to the performance and efficiency of slurry separation equipment. As solids accumulate in pipes, valves, screens, and processing chambers, they can reduce flow capacity, increase system pressure, and place unnecessary strain on key components. If left unaddressed, this buildup can lead to equipment failure, higher energy usage, and costly unplanned maintenance.

To effectively mitigate these issues:

- Schedule Regular Cleanouts: Periodic system shutdowns for deep cleaning are essential. These intervals should be determined based on solids load, operating hours, and manufacturer recommendations. Regular cleanouts restore flow rates and help preserve screen integrity.

- Use Proper Flushing Fluids and Techniques: Avoid using harsh chemicals or high-pressure water unless explicitly approved by the OEM. Aggressive flushing methods can degrade internal linings or deform filtration components, especially in precision-engineered Solid-liquid separation machinery.

- Implement Automated Backflush Systems: For operations that require continuous uptime, integrating automatic backflush systems into your slurry separator machine can greatly reduce manual intervention and improve consistency.

By establishing a disciplined cleaning routine, operators ensure that slurry separation equipment maintains optimal throughput, lowers power consumption, and consistently delivers accurate solid-liquid separation. Especially in facilities handling sticky, abrasive, or fine-particle slurries, proper flushing procedures are essential to extending system longevity and protecting long-term ROI.

Replacement and Calibration of Critical Components

Regardless of how robust, components within slurry separation equipment will eventually degrade over time due to prolonged use. Proactive replacement and calibration are crucial for maintaining system efficiency, accuracy, and safety, particularly in demanding applications such as mining, wastewater treatment, and industrial processing.

Key focus areas include:

- Screens and Filters: These are the first line of defense in any slurry separator machine. Inspect for signs of tearing, clogging, or excessive wear. Replace them based on operating hours or declining separation performance.

- Valves and Flow Meters: Inaccurate readings due to calibration drift can lead to poor separation ratios, wasted energy, and incorrect flow control. Regular calibration ensures operational precision.

- Nozzles and Pressure Components: These parts are vulnerable to erosion over time. Worn components reduce throughput efficiency and contribute to uneven flow distribution.

Utilizing a CMMS (Computerized Maintenance Management System) or even a detailed manual logbook allows teams to monitor component life cycles, cleaning schedules, and calibration intervals. This data-driven approach eliminates guesswork and ensures critical decisions are backed by operational evidence.

Routine replacement and calibration help extend the lifespan of Solid-liquid separation machinery and protect the long-term reliability of your slurry separation equipment in all working conditions.

Training Operators and Maintenance Teams

Even the most advanced slurry separator machine can experience premature failure if not handled correctly. In fact, a significant number of operational issues stem not from equipment design flaws, but from avoidable human error. Proper training is critical to ensure that your investment in slurry separation equipment delivers long-term value.

To mitigate risks and improve reliability:

- Conduct Hands-On Equipment Training: Schedule training sessions led by the OEM whenever possible, particularly after system installation, upgrades, or major maintenance. This helps operators understand system-specific requirements and correct handling procedures.

- Develop Clear Standard Operating Procedures (SOPs): Provide written guidelines for startup, shutdown, emergency response, daily inspections, and preventive maintenance routines. SOPs create consistency and reduce guesswork across shifts.

- Implement Regular Refresher Courses: Continuous education is vital, especially for new employees or teams operating multiple types of Solid-liquid separation machinery. Frequent reinforcement helps maintain best practices over time.

By training your workforce to recognize early warning signs, such as abnormal noise, inconsistent flow, or rising pressure, you enable them to act before issues escalate. Well-trained operators are your first line of defense in maximizing the efficiency and lifespan of your slurry separation equipment.

Leverage Remote Monitoring and Predictive Technologies

Digitalization is reshaping preventive maintenance across industrial sectors. Today’s advanced slurry separation equipment can be equipped with smart sensors that continuously track key performance indicators such as vibration, flow rate, pressure, and solids content in real time. This level of visibility enables a shift from reactive to predictive maintenance, helping teams identify problems before they escalate into costly failures.

Modern monitoring technologies offer several advantages:

- Predictive Maintenance Alerts: Automatically notify operators when equipment metrics suggest component fatigue, inefficiencies, or imminent failure.

- Remote Monitoring: Especially beneficial for remote or unmanned locations such as offshore platforms, tailings ponds, or decentralized water treatment sites where physical inspections are less frequent.

- Integration with IoT and Digital Twin Platforms: Build a virtual model of your slurry separator machine and simulate performance trends to optimize maintenance planning and minimize system disruptions.

Facilities that implement predictive analytics into their Solid-liquid separation machinery often report reductions in unplanned downtime of up to 30%, along with substantial decreases in emergency repair expenses. These technologies offer a clear ROI by improving operational continuity, reducing risk, and enhancing decision-making.

Incorporating smart tools into your slurry separation equipment strategy is no longer optional; it’s a competitive advantage.

Partner with Your Equipment Manufacturer

Your original equipment manufacturer (OEM) is more than just a supplier; they can be a vital partner in extending the life and optimizing the performance of your slurry separation equipment. By proactively involving the manufacturer in your preventive maintenance strategy, you gain access to specialized expertise, best-in-class resources, and ongoing technical support tailored to your exact application.

Key benefits of OEM collaboration include:

- Scheduled Audits and On-Site Inspections: OEM-certified technicians can identify wear patterns, inefficiencies, or system misalignments that in-house teams may miss.

- Customized Spare Parts Kits: Stocking the right parts in advance minimizes downtime and helps ensure that your slurry separator machine can be quickly restored during planned or unplanned outages.

- Updated Maintenance Recommendations: As your site conditions or process demands evolve, the OEM can suggest recalibrations, part upgrades, or configuration changes to ensure your system continues to run smoothly.

For operators of Solid-liquid separation machinery, long-term service agreements often include training programs, software updates, and priority technical support, ensuring your slurry separation equipment consistently performs at optimal levels.

Establishing a strong OEM relationship isn’t just about fixing problems faster; it’s about preventing them altogether and securing long-term operational success.

Protecting Your Investment with Smart Maintenance

Slurry separation equipment is a mission-critical component in fluid-solid separation processes across various industries, including mining, municipal infrastructure, dredging, oil and gas, and industrial operations. When properly maintained, this equipment ensures reliable throughput, system stability, and long-term cost efficiency. A well-executed preventive maintenance program helps protect your investment, minimize downtime, and maximize ROI.

To recap, smart maintenance means:

- Understanding the environmental and operational stressors on your slurry separation equipment

- Establishing regular inspection, cleaning, and flushing routines

- Replacing and calibrating key components like seals, bearings, screens, and valves

- Training teams to safely and effectively operate the system

- Integrating predictive technologies to stay ahead of potential failures

- Partnering with your OEM for long-term support and technical guidance

Whether you’re operating a mobile slurry separator machine in a remote mining site or a permanent Solid-liquid separation machinery setup in a wastewater treatment facility, these best practices apply universally. A disciplined maintenance strategy ensures your slurry separator machine continues to deliver high performance and longevity.

Let Slurry Separation help you maintain your Solid-liquid separation machinery efficiently, reliably, and with confidence.