Slurry separation equipment is used across various industries for solids control during drilling, separation, and waste management. The components such as separators, centrifuges, and hydrocyclones offer versatile designs and robust performance that make them indispensable in oil and gas exploration, mining, construction, environmental remediation, and more industries. Below, we explore the industries that commonly use slurry separators and the benefits they derive from them.

1. Oil and Gas Exploration and Production

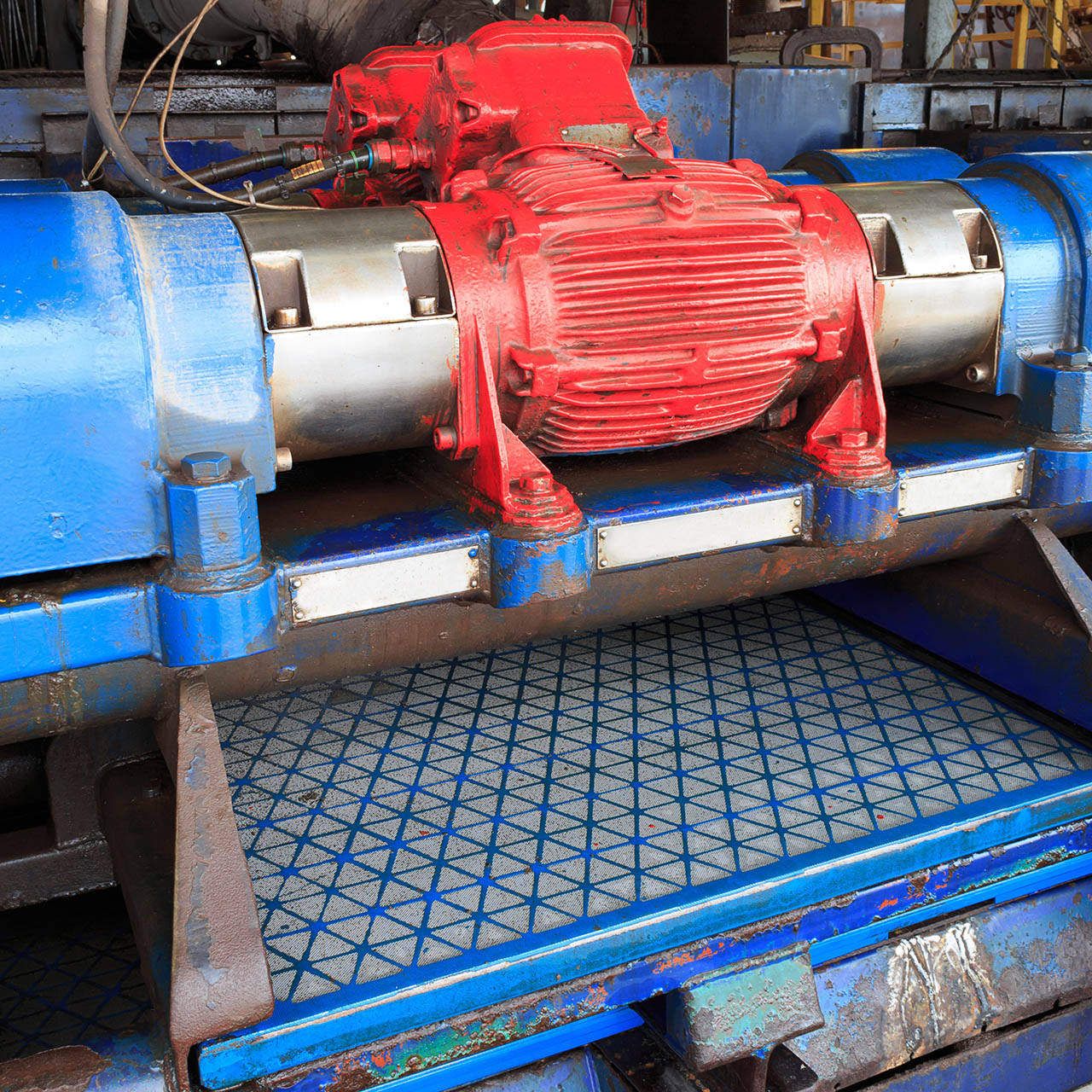

Slurry separation equipment such as separators play a critical role in solids control during drilling operations in the oil and gas industry. They are deployed on drilling rigs to separate drilled solids and cuttings from drilling fluids, ensuring the integrity of the wellbore and optimizing drilling performance. Slurry separators enhance drilling efficiency by removing debris and contaminants from the drilling fluid, preventing equipment wear, and minimizing downtime for maintenance. Additionally, they contribute to environmental protection by containing drilling fluids and cuttings, reducing the risk of contamination of soil and water resources.

2. Mining and Mineral Processing

In the mining industry, slurry separators are utilized for the separation and classification of solids in various mineral processing applications. They are commonly used in ore beneficiation, dewatering, and tailings management processes to remove unwanted solids and impurities from slurries and process streams. Slurry separators help improve mineral recovery rates, reduce water consumption, and minimize environmental impact by efficiently separating valuable minerals from waste materials. Their robust construction and high-capacity processing capabilities make them well-suited for handling abrasive materials and heavy-duty operations in mining and mineral processing plants.

3. Construction and Civil Engineering

In construction and civil engineering projects, slurry separators are employed for solids control and waste management during drilling, excavation, and foundation work. They help remove drilled solids, slurry, and drilling mud from construction sites, ensuring site cleanliness and environmental compliance. Slurry separators facilitate efficient disposal or recycling of drilling waste, reducing project costs and minimizing environmental liabilities associated with waste disposal. Additionally, they contribute to safer working conditions by reducing the risk of slips, falls, and accidents caused by debris accumulation on construction sites.

4. Environmental Remediation and Waste Management

In environmental remediation projects, slurry separators are utilized for solids separation and treatment in contaminated soil and groundwater remediation processes. They help remove contaminants, sediments, and pollutants from soil and water matrices, facilitating the cleanup and restoration of contaminated sites. Slurry separators enable efficient solids control and waste management, allowing for the recovery and treatment of valuable resources while minimizing environmental impact. Their versatility and adaptability make them valuable tools for addressing environmental challenges and ensuring compliance with regulatory requirements.

5. Geothermal Energy and Well Drilling

In geothermal energy and well drilling applications, slurry separators are essential for solids control and wellbore stability during drilling operations. They help remove drilled solids, cuttings, and debris from geothermal fluid streams, preventing clogging and equipment damage downhole. Slurry separators facilitate efficient drilling fluid management and filtration, ensuring the success and longevity of geothermal well installations. Their high-performance capabilities and reliability make them indispensable in geothermal drilling projects, where the integrity of the wellbore is paramount for energy production and reservoir management.

Slurry Separators Remain Critical For Many Industries

Slurry separators are widely utilized across various industries for solids control, waste management, and environmental protection purposes. From oil and gas exploration to mining, construction, environmental remediation, and geothermal drilling, shale shakers play a crucial role in optimizing operational efficiency, minimizing environmental impact, and ensuring regulatory compliance. Their versatility, reliability, and performance make them indispensable tools for industries seeking to improve solids control processes, enhance project outcomes, and mitigate environmental risks across diverse applications and operational contexts.