- Automation and Real-Time Monitoring Capabilities

- Modular and Scalable Design

- High Solids Handling and Abrasion Resistance

- Energy Efficiency and Cost Optimization

- Compliance with Environmental and Safety Regulations

- Mobility and Deployment Flexibility

- Integrated Dewatering and Separation Technologies

- Maintenance, Serviceability, and Uptime

- Investing in the Right Slurry Management System for Long-Term Value

Slurry management systems are no longer a secondary consideration in today’s industrial landscape. They have become a mission-critical operational function. Across various sectors, including mining, oil and gas, municipal wastewater treatment, dredging, tunneling, and power generation, effective slurry management can have a direct impact on project timelines, cost efficiency, and environmental compliance. Failure to implement robust solutions can result in costly downtime, increased equipment wear, and regulatory penalties.

Modern slurry management systems are specifically designed to handle the complex demands of transporting, treating, and disposing of slurry, a dense mixture of water and suspended solids that is often abrasive and challenging to manage. Traditional methods, often pieced together from outdated components, struggle to meet these requirements, resulting in operational inefficiencies, excessive maintenance, and safety concerns.

The industry is shifting toward advanced, modular slurry management systems that are optimized for both performance and flexibility. These systems integrate real-time monitoring, automation, and smart controls, allowing operators to respond quickly to changing conditions while reducing labor costs and human error.

Additionally, they incorporate effective slurry waste management strategies that minimize environmental impact and streamline disposal. From automated flow control to integrated dewatering modules, today’s systems are engineered for safer, smarter, and more scalable operation.

Automation and Real-Time Monitoring Capabilities

One of the most impactful advancements in modern slurry management systems is the integration of automation and real-time monitoring. Manual operation of pumps, valves, and flow systems, once common in many industries, is not only inefficient but poses significant risks, especially in high-volume, high-pressure slurry environments. Delays in response or human error can lead to serious safety hazards, unplanned downtime, or even regulatory violations.

Today’s intelligent slurry management systems are designed with automated controls that actively regulate critical variables, such as flow rate, pressure, and solids concentration. These smart systems continuously adjust performance based on incoming data, helping to prevent overflows, line blockages, and equipment failures. The result is a more consistent, efficient operation that conserves energy and reduces wear on pumps and piping.

Real-time monitoring is enabled through the integration of SCADA platforms, IoT-connected sensors, and telemetry modules. These tools provide remote visibility into system conditions, allowing operators to access performance data from centralized control rooms or mobile devices in the field. Early warnings and predictive analytics enable teams to intervene before small issues escalate into costly disruptions.

Automated control systems offer multiple strategic advantages:

- Reduce labor costs by minimizing manual oversight

- Improve operational safety by removing workers from hazardous zones

- Enhance process consistency and fluid control

- Support compliance with slurry waste management regulations through better system tracking

In high-stakes industrial environments, automation doesn’t just add convenience; it creates a smarter, more responsive infrastructure that supports both performance and compliance objectives, making the operation more comfortable for the team.

Modular and Scalable Design

Today’s slurry management systems are designed with adaptability in mind. Gone are the days of rigid, “one-size-fits-all” solutions. In industries where flow rates, slurry composition, and operational demands change rapidly, such as mining, dredging, and large-scale construction, scalability and modularity have become essential design features, making the system more adaptable and versatile.

For example, mining operations often face varying output levels as excavation zones evolve. This creates a need for slurry systems that can scale accordingly. Modular units, whether pumps, separators, or dewatering skids, can be added or removed in response to shifting throughput requirements, enabling efficient resource allocation and cost control.

Modular slurry management systems can be configured for both long-term installations and short-term project deployments. This makes them highly attractive to contractors, engineering firms, and municipal buyers who must respond quickly to seasonal surges or emergency conditions. Whether you’re handling continuous dewatering or managing a rapid-response slurry containment issue, modular systems offer reliable performance with minimal setup time.

Beyond flexibility, modularity also enhances slurry waste management by facilitating the easier integration of separation technologies and containment units. This ensures both regulatory compliance and environmental stewardship in dynamic field conditions.

High Solids Handling and Abrasion Resistance

Slurry is rarely a uniform substance. It often contains a challenging mix of sand, silt, gravel, industrial byproducts, and organic matter. These abrasive and dense components can cause significant damage to traditional pumping equipment, resulting in frequent breakdowns, excessive maintenance, and costly downtime.

Modern slurry management systems are engineered specifically to withstand such harsh conditions. They incorporate robust components designed for maximum durability and long-term reliability in high-solids environments.

Key design features include:

- Wear-resistant linings made from hardened rubber, ceramics, or specialized polymers that protect internal surfaces from erosion.

- Hardened impellers capable of withstanding constant impact from sharp, coarse materials.

- Heavy-duty mechanical seals are designed to maintain integrity and prevent leakage, even under severe abrasion and pressure.

These advancements significantly extend equipment lifespan and reduce the frequency of unexpected repairs. When selecting from available slurry management systems, it’s essential to assess their solid-handling capabilities, typically expressed as a percentage of solids by weight, and their abrasion resistance ratings.

Efficient handling of dense slurry also improves the outcomes of slurry waste management. By minimizing water content and maximizing the movement of solids, operations can reduce disposal costs, conserve water, and meet increasingly strict environmental standards. This level of performance is especially crucial in mining, tunneling, and industrial waste applications, where abrasive materials are prevalent.

Energy Efficiency and Cost Optimization

For operations that run pumps continuously, energy consumption is a significant operational expense. Legacy systems are often built without modern efficiency standards, consuming excessive power due to outdated motors, inefficient hydraulic pathways, and the absence of intelligent control features. Over time, these inefficiencies significantly increase both operating costs and environmental impact.

Modern slurry management systems are designed with energy efficiency as a core feature. They incorporate:

- High-efficiency motors (IE3 or IE4 rated) that deliver superior output with lower energy draw

- Streamlined piping and flow paths to reduce friction losses and minimize head requirements

- Variable Frequency Drives (VFDs) that allow dynamic pump speed adjustment based on real-time process loads

VFDs are particularly valuable in slurry management systems with variable flow demands. Instead of running at maximum capacity constantly, operators can fine-tune pump speeds to match actual conditions, leading to significant reductions in power consumption.

When viewed through a Total Cost of Ownership (TCO) lens, energy-efficient systems often pay for themselves quickly. Lower utility bills, fewer mechanical failures, and reduced downtime all contribute to faster ROI.

In addition to operational savings, improved energy efficiency supports better slurry waste management by ensuring smoother flow, reduced clogging, and more consistent handling of material densities, further streamlining the overall process from intake to discharge.

Compliance with Environmental and Safety Regulations

In today’s regulatory landscape, environmental and worker safety compliance is not just best practice; it’s a legal requirement. Agencies like the EPA, OSHA, and local environmental authorities are increasing scrutiny on operations that handle wastewater, industrial byproducts, and high-solid materials. Failure to comply can result in hefty fines, project delays, and reputational damage.

Modern slurry management systems are engineered to meet or exceed these regulatory demands.

Key features that support compliance include:

- Closed-loop operation that prevents untreated slurry from being discharged into natural water bodies.

- Spill containment systems and sensor-activated alarms to detect and manage leaks or overflows.

- Low-emission engines and noise-dampening features are ideal for work in urban zones or environmentally sensitive areas.

- Enhanced solids capture mechanisms to reduce the volume of waste requiring off-site disposal.

In addition, advanced slurry management systems often come equipped with leak detection technology, automated chemical dosing units, and emergency shutdown protocols safeguarding both equipment and personnel.

Procurement and project managers should prioritize equipment that is compliant with ANSI, ISO, and other industry-specific certifications to ensure readiness for audits and inspections.

By improving operational safety and reducing environmental impact, these systems also support more sustainable slurry waste management practices, a crucial factor in securing public contracts and maintaining long-term site approvals.

Mobility and Deployment Flexibility

Many industrial and municipal projects occur in challenging environments, such as remote locations, unstable ground, or confined spaces, where traditional equipment setups are often not feasible. In these situations, the mobility of modern slurry management systems becomes a critical asset.

Today’s systems are built with portability in mind. Skid-mounted and trailer-based slurry units provide rapid deployment and repositioning, enabling teams to respond quickly to changing site conditions. During events such as flooding, sewer line failures, or pipeline maintenance, a mobile slurry system can be delivered, set up, and made operational within a matter of days, then removed just as easily once the job is complete.

Key advantages of mobile slurry management systems include:

- Quick installation and removal to keep projects on schedule

- Minimal site preparation, reducing the need for permanent infrastructure

- Lower upfront capital expenditure, especially when systems are rented

Rental-based models are especially valuable for government agencies and contractors managing seasonal workloads or short-duration projects. They offer the flexibility to scale operations without long-term commitments, while maintaining performance and compliance.

Additionally, mobile units can be equipped with on-board separation or containment features to enhance slurry waste management, making them suitable for projects in environmentally sensitive or regulatory-heavy areas.

Integrated Dewatering and Separation Technologies

Modern slurry management systems do more than transport slurry; they also treat it through integrated dewatering and separation technologies. These features are crucial for operations seeking to minimize disposal costs, comply with environmental regulations, and operate efficiently in remote or temporary settings.

Common separation technologies found in advanced slurry management systems include:

- Hydrocyclones for rapid particle separation

- Centrifugal separators to isolate fine solids

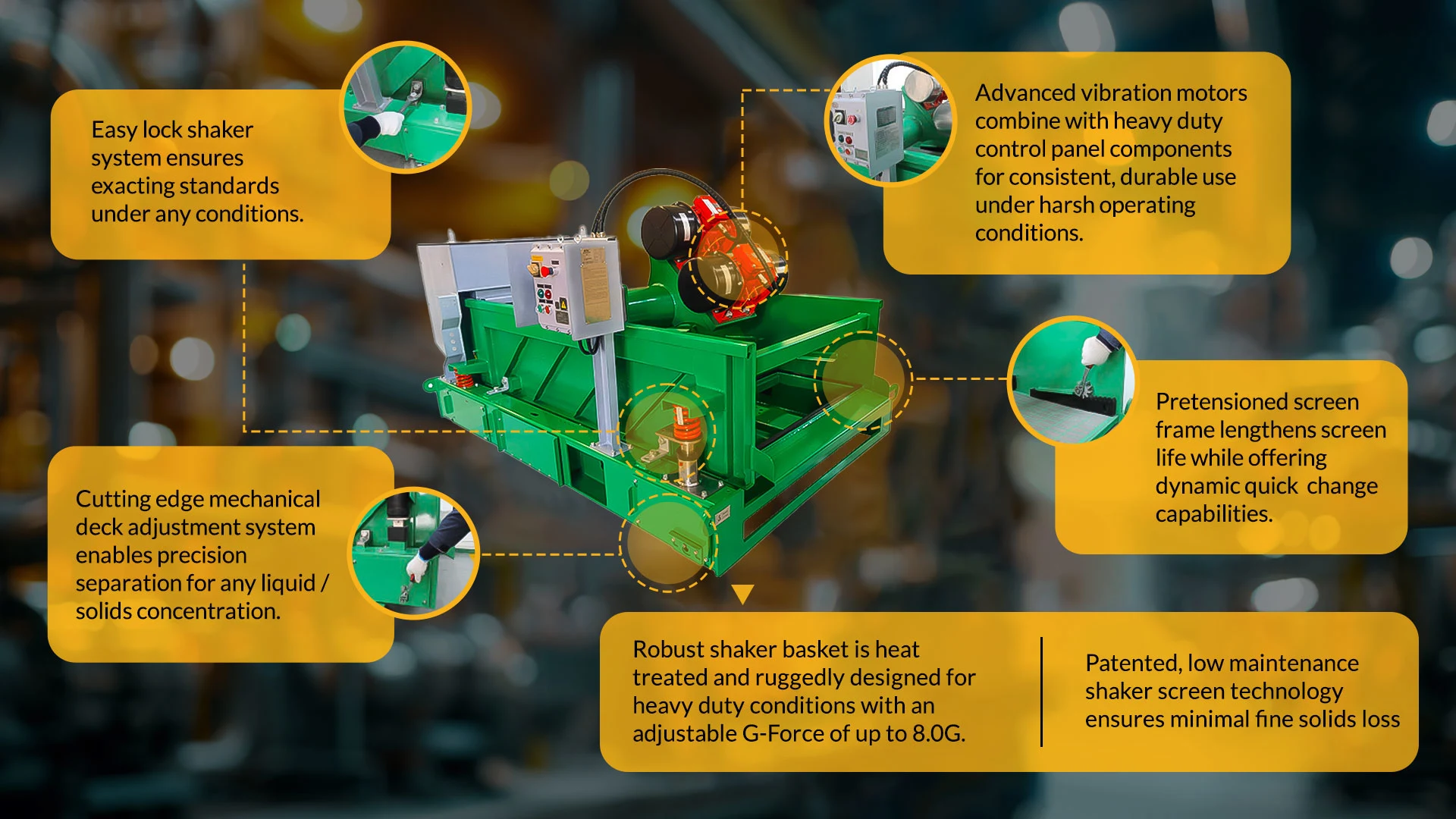

- Vibratory dewatering screens that remove excess water from the charged material

- Geotextile dewatering bags for passive filtration in field-based applications

By extracting reusable water and concentrating solids, these systems significantly improve operational sustainability and cost-effectiveness.

Effective slurry waste management through separation reduces:

- The total volume of waste requiring transport and disposal

- Hauling and landfill expenses

- Environmental and regulatory risk due to improper handling

In projects where trucking liquid waste is cost-prohibitive or where disposal regulations are strict, turnkey systems with built-in separation modules are not just beneficial, they’re essential for compliance and operational continuity.

Maintenance, Serviceability, and Uptime

No matter how advanced, a system’s true value lies in its uptime. In critical operations, every hour of equipment failure leads to lost productivity, project delays, and potential non-compliance. That’s why modern slurry management systems are built with maintainability and serviceability at their core.

Key design features include:

- Tool-free access panels that allow technicians to inspect, clean, and replace components quickly

- Remote diagnostics and real-time alerts that help operators identify issues before they escalate

- Standardized, interchangeable parts to reduce repair times and inventory complexity

- OEM-backed rental support, including 24/7 assistance and fast access to replacement units or parts

The best-performing slurry management systems are those that minimize downtime through intelligent design and comprehensive support services. Procurement teams should prioritize equipment providers that offer detailed maintenance plans, spare parts availability, and guaranteed response times.

Additionally, simplified maintenance workflows enable technicians to perform routine servicing without specialized tools or prolonged shutdowns, further increasing operational uptime and ROI.

Reliable maintenance also supports better slurry waste management, as consistent equipment performance ensures steady flow rates, proper solids handling, and reduced risk of environmental incidents due to system failure.

In high-stakes environments, systems designed with uptime in mind deliver not just performance but peace of mind.

Investing in the Right Slurry Management System for Long-Term Value

Choosing the right solution for slurry handling isn’t just a capital expenditure; it’s a strategic investment with long-term implications for productivity, compliance, and profitability. In high-demand industries, the performance of your slurry management systems has a direct impact on project outcomes, regulatory compliance, and operating costs.

By focusing on key features such as:

- Real-time automation and monitoring

- Modular design, scalability, and mobility

- Abrasion resistance and high solids handling

- Integrated separation and dewatering capabilities

- Energy efficiency and environmental compliance

- Easy maintenance and full service support

Your team can transform slurry management systems from a potential bottleneck into a competitive advantage.

Reliable systems not only improve uptime and reduce downtime—they also enable better slurry waste management by handling solids more efficiently, minimizing disposal volumes, and supporting closed-loop operations that meet today’s strict environmental standards.

Whether you’re managing a mining pit, infrastructure repair, dredging project, or municipal bypass, investing in high-performance slurry management systems ensures measurable returns in safety, system longevity, and compliance.

Need Help Finding the Right System?

Slurry Separation specializes in turnkey slurry management solutions, including rentals for both short- and long-term use. Our fleet of skid-mounted, trailer-based, and fully integrated units is ready for immediate deployment.

Let us help you take control of your slurry waste management efficiently, safely, and with maximum ROI.