Drilling operations are intricate and demanding, requiring a combination of advanced technology, skilled personnel, and precise execution to achieve success. Whether it’s oil, natural gas, or geothermal drilling, the complexity of managing the entire process—especially deep in the earth’s subsurface—is significant. Each phase of drilling demands careful planning and coordination to overcome challenges posed by varying geological formations, equipment limitations, and environmental factors. Central to these operations is the bore hole, which must be properly drilled, maintained, and kept clean to ensure efficient progress and prevent solids buildup.

One of the critical components of drilling operations is maintaining the quality of drilling fluid, commonly known as drilling mud. Drilling rigs serve as the primary machinery used in these operations, supporting the entire drilling process. This specialized fluid plays a vital role in cooling and lubricating the drill bit, stabilizing the wellbore, and carrying rock cuttings to the surface. However, as the fluid recirculates, it can become contaminated with various-sized particles and solids, making effective management essential to ensure its continued efficiency. Poorly managed drilling fluid can result in equipment damage, operational delays, and increased costs.

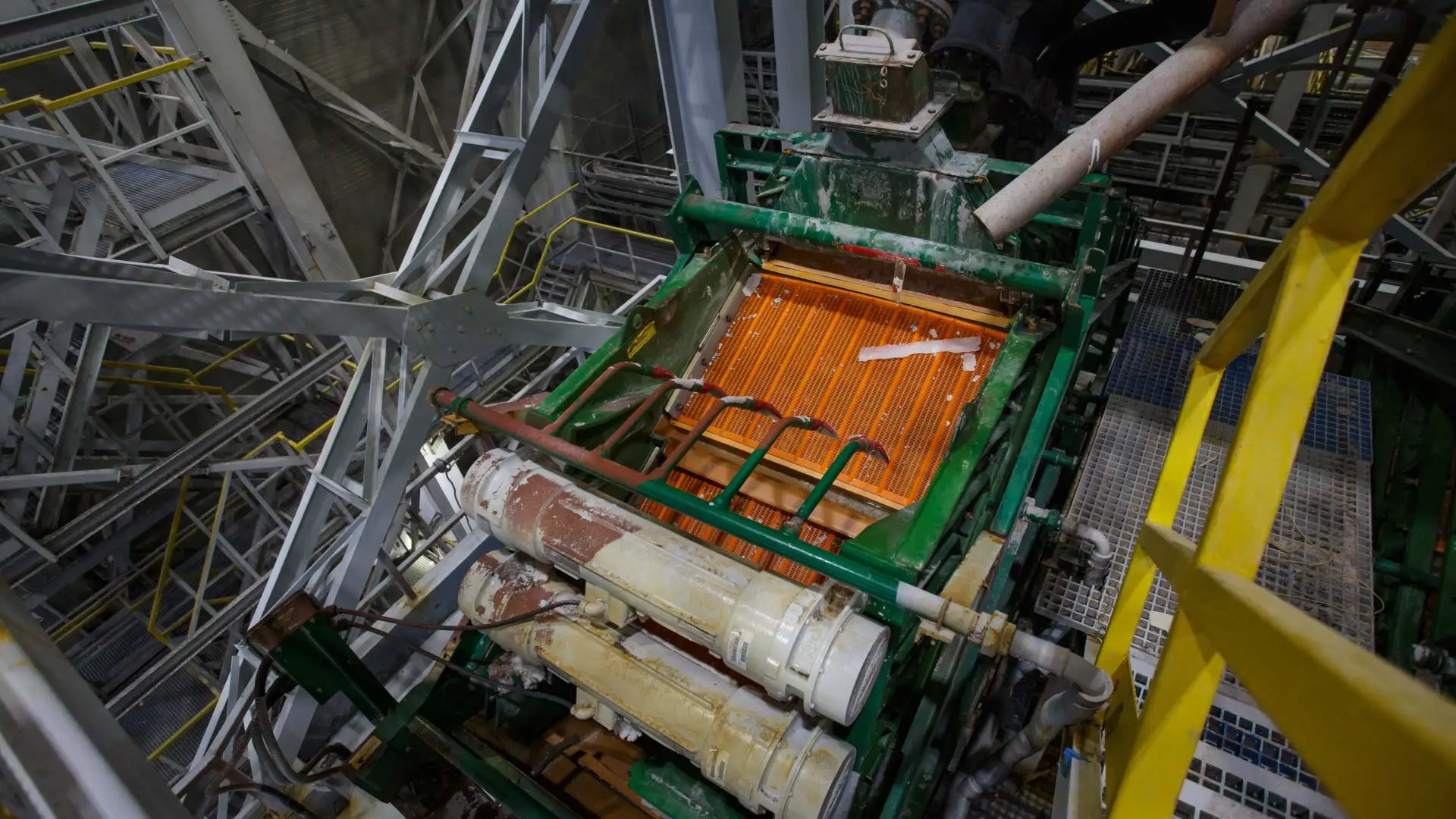

To maintain the integrity and performance of drilling fluid, effective solids control systems are indispensable. These systems are designed to remove unwanted solids from the mud, allowing it to be reused efficiently while minimizing waste and reducing environmental impact. At the heart of these systems is the shale shaker, an important device in the solids control system that acts as the first line of defense in solids control.

Equipped with shale shaker screens, this device is responsible for separating large cuttings from the drilling fluid through a combination of vibration and screen filtration. By ensuring that only reusable drilling fluid passes through to subsequent purification stages, the shale shaker not only optimizes fluid quality but also protects downstream equipment from unnecessary wear and tear. In this article, we will explore the role of shale shakers in detail, understand how they work, how they improve performance and examine the latest technological advancements shaping their performance.

What is a Shale Shaker?

A shale shaker is a vital piece of machinery used in the process of drilling operations to remove larger solid particles, such as rock cuttings, from the drilling fluid. Its primary purpose is to remove solids from drilling fluid, ensuring that the fluid remains effective and preventing equipment overload. It is typically located at the very start of the solids control system. Alongside the shale shaker, other solids control equipment such as desanders, desilters, and vibrating screens work together to further separate solids and maintain the quality of the drilling mud. It serves to prevent large solids from entering subsequent stages, thus enhancing the overall efficiency of fluid management.

Definition and Basic Function

At its core, a shale shaker is a vibrating screen mechanism where drilling fluid enters through a designated inlet before being processed. Equipped with shale shaker screens, it allows smaller particles and clean drilling fluid to pass through its mesh screens, with the effectiveness of separation depending on the selected screen mesh. Using the appropriate screen mesh is crucial for efficient filtration, as it filters out the larger particles that must be disposed of. This process ensures that the remaining fluid is relatively clean, preventing unnecessary wear on downstream equipment and optimizing mud properties.

Role as the First Line of Defense in Solids Control

The solid control system relies on the shale shaker as the first and primary line of defense in the solids control process. Removing large solids early in the process is crucial for protecting downstream equipment, such as desanders, desilters, and centrifuges, from being overloaded with debris. Efficiently removing solids at this stage helps prevent excessive wear and tear on these devices and ensures that the drilling fluid remains effective in its many roles during the drilling process.

Types of Shale Shakers

There are several types of shale shakers, each designed for specific applications based on operational needs. The motion type—such as linear, elliptical, or circular vibration—varies between shaker designs and significantly affects separation efficiency:

- Single-Deck Shakers: These are the simplest form of shale shakers, featuring a single deck of shale shaker screens that handle the separation process.

- Double-Deck Shakers: Double-deck shakers use two layers of screens, providing an extra level of filtration for enhanced performance. The use of multiple layers of screens with different mesh sizes helps remove finer solids from drilling fluids.

- Triple-Deck Shakers: These shakers are used in larger operations and feature three decks, which allows for improved separation and greater capacity. Multiple layers of screens further enhance the solids control process by increasing separation efficiency.

Choosing the right type of shale shaker is essential to meet the specific needs of a drilling operation effectively.

Overview of Shale Shaker Types

Shale shakers are indispensable in the solids control system of drilling operations, especially in oil and gas drilling, where efficient separation of drill cuttings from drilling fluid is essential for maintaining drilling efficiency and protecting downstream equipment. The primary types of shale shakers—linear motion, elliptical motion, and balanced elliptical motion—each offer distinct advantages tailored to specific drilling environments and operational requirements.

Linear motion shakers are renowned for their high throughput capacity, making them ideal for drilling operations with high flow rates and significant volumes of drilling fluid. Their robust design ensures effective removal of solids, which is crucial in fast-paced drilling environments such as gas drilling. In contrast, elliptical motion shakers provide a gentler action, which helps extend screen life and enhances solids separation efficiency, particularly in scenarios where minimizing maintenance costs and maximizing screen longevity are priorities. Balanced elliptical motion shakers combine the benefits of both, offering versatility across a range of drilling conditions.

Selecting the right type of shale shaker is vital for optimizing the solids control system, improving drilling efficiency, and reducing operational costs. By understanding the unique characteristics and applications of each shaker type, operators can ensure their equipment is well-matched to the demands of their drilling operations.

Linear Motion Shale Shakers

Linear motion shale shakers are a cornerstone of modern drilling operations, prized for their ability to efficiently process large volumes of drilling fluid and remove solid particles from the system. Utilizing two synchronized motors, these shakers generate a powerful straight-line motion that propels solids rapidly across the screen surface, ensuring effective separation and discharge.

This high-capacity design makes linear motion shakers particularly well-suited for drilling environments where high flow rates and substantial solid loads are common. Their robust performance helps maintain the integrity of the drilling fluid, supporting continuous drilling operations and minimizing the risk of equipment downtime. However, the aggressive movement of solids can lead to increased wear on screens, potentially reducing screen life if not properly managed.

To maximize the benefits of linear motion shale shakers, it is essential to select screens that are compatible with the specific drilling fluid and operational conditions, and to implement regular maintenance routines. By doing so, operators can achieve optimal throughput capacity, maintain efficient solids control, and ensure reliable performance throughout the drilling process.

Elliptical Motion Shale Shakers

Elliptical motion shale shakers offer a unique approach to solids separation by employing an elliptical movement of the screen basket, generated by two slightly out-of-phase motors. This motion provides a gentler handling of the drilling fluid and drill cuttings, which is especially advantageous in drilling operations where preserving screen life and maximizing solids separation efficiency are top priorities.

The elliptical motion is particularly effective in environments with finer solids, as it allows for more thorough separation without subjecting the screens to excessive stress. This results in longer screen life and reduced maintenance requirements, contributing to lower overall operational costs. Additionally, elliptical motion shakers are highly adaptable, capable of handling a wide range of drilling fluid properties and performing reliably under different drilling conditions.

Their versatility and ability to deliver high-quality separation make elliptical motion shale shakers a popular choice in the oil and gas industry, especially for operations that demand both efficiency and durability in challenging drilling environments.

Shaker Design

The design of a shale shaker plays a pivotal role in its effectiveness within the solids control system, directly impacting separation efficiency, screen life, and overall drilling performance. Key design elements include the type of motion—whether linear, elliptical, or balanced elliptical—which determines how solids are conveyed and separated from the drilling fluid.

Vibration frequency and stroke length are critical parameters that influence the G-force applied to the fluid and solids, affecting both the throughput capacity and the efficiency of solids removal. A higher G-force can improve separation efficiency but may also accelerate screen wear, so finding the right balance is essential for optimal performance. The screen surface area and mesh size are equally important, as they dictate the volume of fluid that can be processed and the size of solids that can be effectively removed.

The shaker basket design, including the deck angle and feed box configuration, ensures even distribution of drilling fluid across the screen surface, promoting efficient solids removal and minimizing fluid losses. Modern shale shaker designs often incorporate advanced materials and innovative technologies to enhance durability, reduce maintenance needs, and support environmental sustainability.

By understanding and prioritizing these key design elements, operators can select shale shakers that are best suited to their specific drilling conditions, ensuring reliable performance and efficient solids control throughout the drilling operation.

How Shale Shakers Work

To fully appreciate the critical role of shale shakers in drilling operations, it’s essential to understand their fundamental principles, mechanisms, and contribution to efficient solids control. Shale shakers process drilling fluid by separating drilled solids from the fluid, ensuring cleaner mud is recirculated back into the well.

Maintaining proper drilling fluid flowing through the shaker is crucial for optimal performance, as it ensures continuous removal of cuttings and prevents issues such as screen clogging or equipment inefficiencies.

Working Principle

Shale shakers work by vibrating screens at high frequencies to separate drill cuttings from the drilling fluid. As drilling fluid is pumped out of the well, it passes across the shale shaker screens. This rapid vibration helps filter out large solids while allowing the fluid to flow through the screen and continue to the next phase of cleaning.

- Vibration Patterns: Shale shakers employ different types of vibration patterns—linear, elliptical, or circular—each providing varying levels of efficiency. Linear motion is typically preferred for high-volume drilling, while elliptical or circular vibrations are often used for more precise separations. The use of strong vibration in high-frequency shakers enhances separation efficiency and helps prevent screen clogging, especially in demanding drilling applications.

- Mesh Sizes: The effectiveness of a shale shaker largely depends on the type of mesh screens used. Mesh sizes are designed to filter out different particle sizes; finer mesh screens are essential for capturing fine solids, which are challenging to remove but critical for maintaining fluid clarity and wellbore stability. The choice of mesh size depends on the nature of the solids being separated and the desired purity of the fluid.

Key Components of a Shale Shaker

- Deck: The structural platform that holds the screen. The top deck is the initial point where drilling mud is distributed onto the screens, ensuring even coverage for maximum solids removal efficiency. The deck is subjected to vibration to help separate solids.

- Screen: The screen is the primary separating surface, filtering out larger cuttings while allowing smaller particles and fluid to pass through. Screen frames support the screens and are designed for quick-swap and modular maintenance, enabling efficient screen changes and reducing downtime.

- Basket: The basket holds the screens and screen frames in place and facilitates ease of operation, including quick screen replacement.

- Motor: The vibrating motor powers the oscillation, driving the separation process by generating the necessary frequency and amplitude of movement.

Each of these components must function correctly to ensure that the shale shaker can effectively remove unwanted solids.

Importance of Shale Shakers in Drilling Operations

Shale shakers play a crucial role in maintaining the efficiency, cost-effectiveness, and safety of drilling operations. Effective solids control, including the removal of larger solids from drilling fluids, is essential for successful well construction, as it helps prevent equipment damage and ensures optimal drilling performance. Let’s explore their contributions in greater detail.

Mud Recycling and Cost Reduction

Shale shakers allow the recovery and reuse of drilling fluid by removing solid particles that could otherwise contaminate the mud. After solids are separated, the cleaned drilling fluid is directed for further use in the drilling process, supporting efficient resource management. This reduces the need to add new mud, resulting in considerable cost savings constantly. Equipped with high-quality shale shaker screens, these systems ensure efficient solids control, which also minimizes wear and tear on pumps and other machinery that rely on high-quality mud.

Impact on Equipment Longevity

By removing solid particles from the drilling fluid early, shale shakers protect downstream equipment, including mud pumps and centrifuges. To prevent equipment damage and maintain efficient solids control, all drilling fluid should be properly screened to remove undesirable solids before reaching downstream components. Abrasive particles in drilling fluid can cause severe wear to pumps, valves, and pipework, leading to frequent maintenance and downtime. Shale shaker screens play a vital role in this process by ensuring cleaner fluid is used, thereby extending the life of these components.

Environmental Compliance

Effective solids control is important from an environmental standpoint as well. Proper management of drilling waste reduces the volume of contaminated fluid, making it easier to comply with environmental regulations and minimize the environmental impact of drilling operations. The mud system plays a crucial role in managing and treating drilling waste, ensuring that solids are efficiently separated and processed to meet environmental compliance standards.

Prevention of Wellbore Instability

Excessive solids in the drilling fluid can cause significant issues, such as high equivalent circulating density (ECD), which may lead to wellbore instability. Maintaining clean drilling fluid helps reduce these risks, ensuring a stable drilling process.

Key Factors in Choosing the Right Shale Shaker

Selecting the appropriate shale shaker for a drilling operation requires careful consideration of various factors. Choosing a high performance shale shaker is crucial, as it ensures optimal efficiency, superior vibration control, and reliable operation even in demanding drilling conditions. Here are some key points to keep in mind:

Compatibility with Drilling Fluid

Different types of drilling fluids require specific equipment to function effectively. High-viscosity fluids, for example, require a shaker with different vibration settings compared to lighter fluids. Ensuring compatibility helps improve efficiency and prevent performance issues. Additionally, different drilling environments—such as variations in well depth, mud weight, and environmental conditions—demand shale shakers with features tailored for optimal performance in those specific settings.

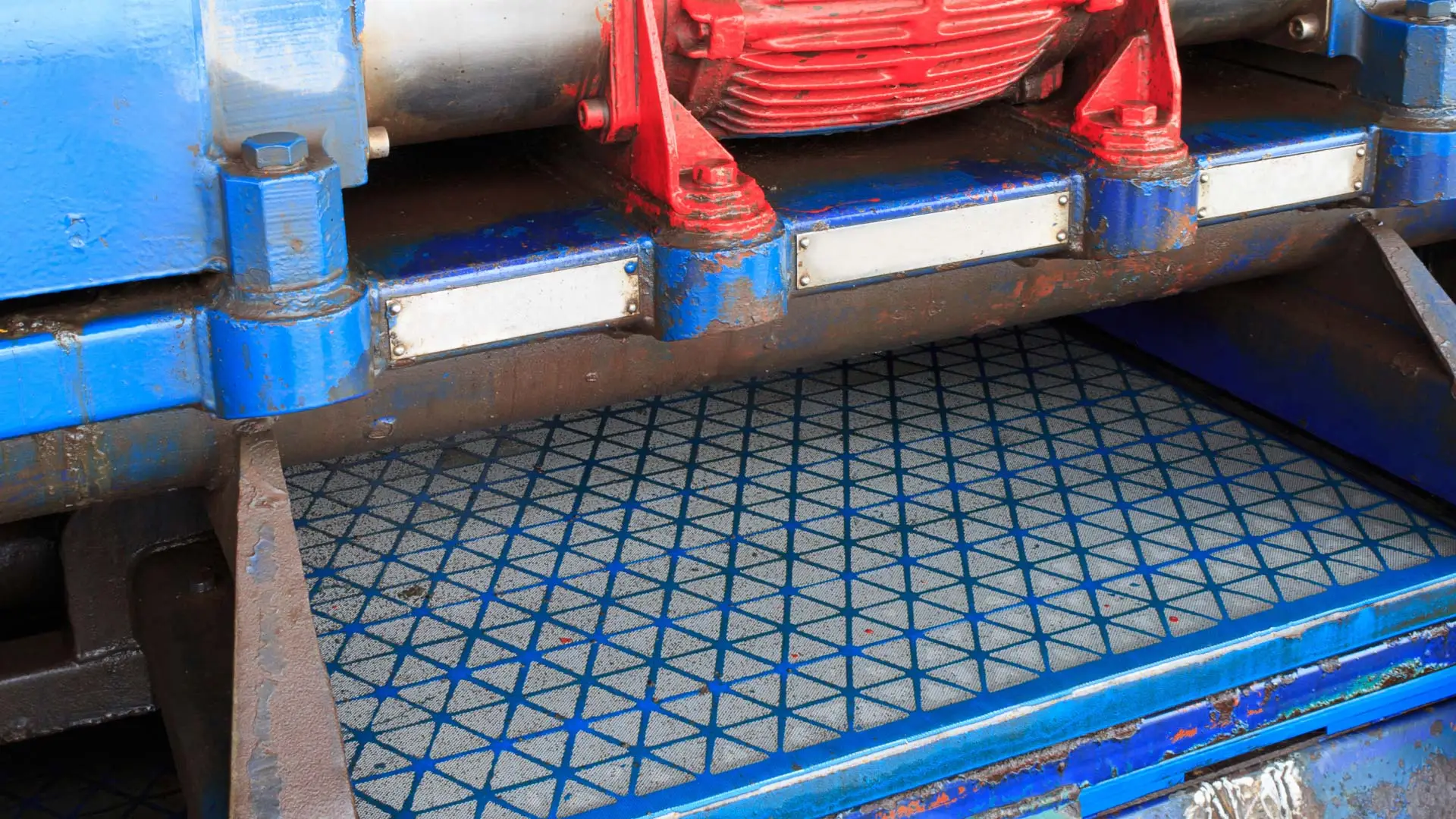

Screen Type and Durability

Screens are the most critical component of a shale shaker, as they directly influence separation efficiency. The type of screen—whether metal or composite—impacts the shaker’s durability and effectiveness. Both traditional and modern shale shaker screens commonly use wire mesh as the filtering and separation medium, which helps retain solid particles while allowing fluids to pass through. High-quality shale shaker screens, such as composite screens, tend to last longer and are more resistant to damage compared to traditional metal screens, making them a preferred choice for demanding operations.

Adjustability of Vibration Speed and Angle

Modern shale shakers allow operators to adjust the speed and angle of vibration to optimize performance. This adjustability is particularly important when dealing with different types of drilling conditions or mud compositions.

Maintenance and Operational Reliability

The ease of maintenance is another important consideration. Look for a shale shaker that allows for quick screen replacement, easy motor servicing, and features components that are readily accessible. Operational reliability also depends on selecting equipment with a strong track record of consistent performance.

Common Challenges and Troubleshooting Tips

Like all equipment, shale shakers can face challenges during operation. After the drilling fluid passes through the shale shaker, the processed fluid is collected in mud tanks for further treatment or storage. Understanding these challenges and knowing how to troubleshoot them can enhance shaker performance.

Common Challenges

- Screen Blinding: When particles stick to the screen and block its openings, it is known as screen blinding. This reduces the efficiency of the shaker and results in poor fluid separation.

- Poor Vibration: If the motor or vibratory mechanism is faulty, the vibration may not be sufficient to achieve effective separation. This can lead to improper functioning of the shale shaker.

- Screen Wear: With constant use, shale shaker screens undergo wear and tear, making them less effective at filtering solids. Regular replacement is necessary to maintain optimal performance.

Troubleshooting Tips

- Regular Cleaning: Cleaning the screens regularly prevents blinding and ensures they function correctly. Operators should remove any debris and replace clogged screens.

- Monitor Vibration Mechanism: Regular inspections of the vibrating motor can identify issues early. Checking for signs of motor malfunction, such as erratic motion or unusual noise, can prevent costly failures.

- Replace Worn Screens: Ensure that worn-out screens are replaced promptly. Operating with damaged screens reduces separation efficiency and can affect downstream equipment.

Advances in Shale Shaker Technology

Advances in technology have brought significant improvements to shale shaker design and performance, making them more efficient, reliable, and environmentally friendly. These enhancements address some of the most pressing challenges in solids control and provide drilling operators with better tools to manage drilling fluid quality.

Innovations in Screen Designs

Modern shale shakers utilize composite screens that offer a range of benefits over traditional metal screens. These shale shaker screens are engineered to deliver increased strength and flexibility, reducing the likelihood of damage during demanding operations. Composite screens also have superior fluid handling capabilities, allowing for greater separation efficiency. Additionally, they boast a longer operational life, reducing the need for frequent replacements and lowering overall maintenance costs. These advancements make composite screens an essential upgrade for improving shale shaker performance in challenging drilling environments.

Automation and Real-Time Monitoring

The integration of automation has revolutionized shale shaker technology. Advanced systems now include automated monitoring features that track screen conditions and performance metrics in real time. This technology enables operators to make on-the-fly adjustments based on the type and viscosity of the drilling fluid. Remote monitoring capabilities further enhance efficiency by allowing operators to oversee vibration levels, screen wear, and other critical factors without being physically present at the site.

Energy-Efficient Designs

Recent innovations have prioritized energy efficiency, reducing power consumption without sacrificing performance. Energy-efficient shale shakers help minimize environmental impact and lower operational costs, making them a more sustainable option. Some models are also designed to maximize fluid recovery, minimizing waste while ensuring that drilling fluids are recycled effectively.

These technological advancements make modern shale shakers indispensable for improving drilling efficiency and minimizing environmental and operational risks.

Conclusion

In drilling operations, shale shakers are the front-line defenders in maintaining drilling fluid quality. Their critical role in separating solids from the drilling fluid contributes significantly to operational efficiency, reduced equipment wear, and environmental compliance. Equipped with high-quality shale shaker screens, these systems ensure precise solids control, which is essential for maintaining the effectiveness of drilling fluid and prolonging equipment life. Investing in high-quality shale shakers and prioritizing regular maintenance ensures long-term success in challenging drilling environments.

As technology advances, the capabilities of shale shakers continue to evolve. Innovations in screen designs, automation, and energy-efficient models have enhanced their performance, making them more effective and easier to operate. By upgrading to advanced shale shaker screens and regularly servicing equipment, operators can achieve optimal performance and adapt to the demands of modern drilling operations.

For more information about solids control systems or to speak with an expert about choosing the right shale shaker for your drilling needs, don’t hesitate to contact us. We offer a range of resources and technical guides to help you optimize your operations.