- Introduction

- What Is a Rock Shaker Screen?

- Types of Rock Shaker Screens

- How Rock Shaker Screens Work in the Drilling Cycle

- Key Functions of Rock Shaker Screens in Drilling Optimization

- Common Applications Beyond Oil & Gas

- How to Choose the Right Rock Shaker Screen

- Maintenance Tips to Maximize Screen Life

- Innovations and Future Trends in Shaker Screens

- Conclusion

Introduction

Modern oil and gas drilling operations demand a high level of efficiency, precision, and cost control. As drilling depths increase and formations become more complex, performance optimization relies heavily on the effectiveness of solids control systems. A critical yet often underappreciated component in this system is the rock shaker screen, a primary line of defense in fluid management that plays a pivotal role in overall drilling success.

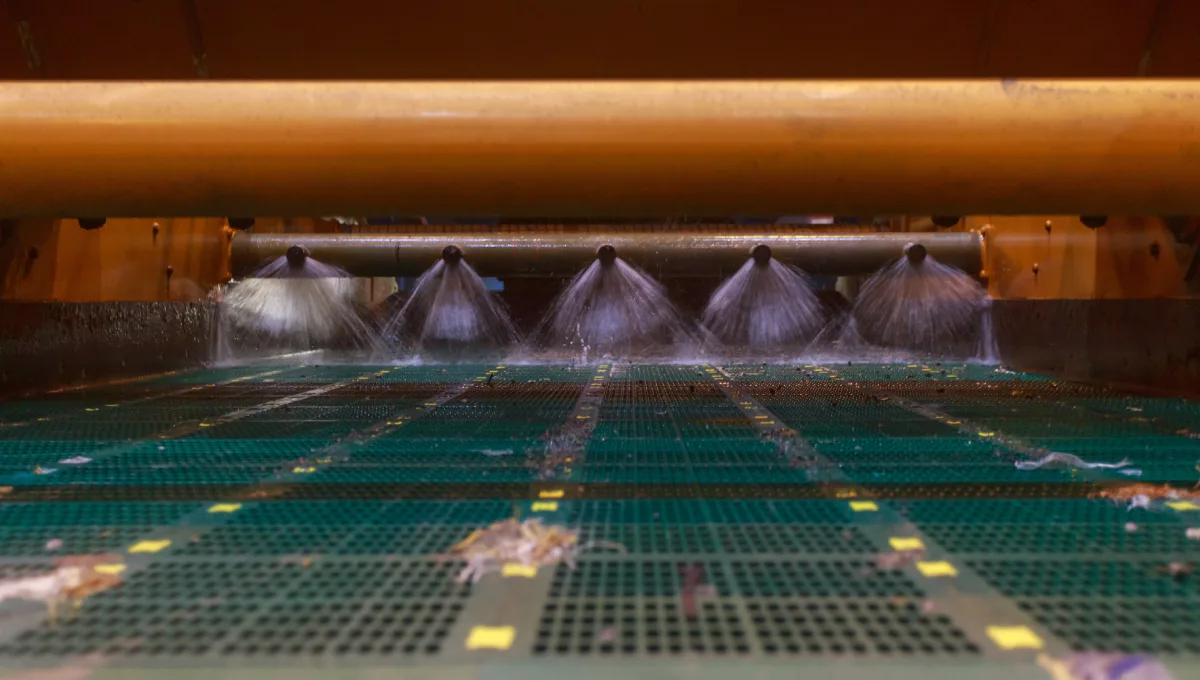

Solids control systems are designed to separate unwanted drill cuttings and solids from valuable drilling fluid. This fluid, essential for cooling the drill bit and maintaining downhole stability, must remain clean and consistent. The shaker deck screen, housed within the shale shaker unit, is where this separation process begins. As drilling mud returns to the surface, it flows over the vibrating screen, which filters out solids while allowing reusable fluid to pass through.

Whether you’re operating in oilfields or applying similar technology in environmental projects, such as using a shaker screen for dirt in construction or trenchless drilling, the function and quality of the rock shaker screen directly impact project efficiency. This article examines how selecting and maintaining the right shaker screen can optimize drilling performance, minimize downtime, and reduce operational costs.

What Is a Rock Shaker Screen?

A rock shaker screen is a vital component of the solids control system, specifically designed to filter out drilling cuttings from the returning drilling fluid. Installed on a shale shaker unit, the screen serves as the first stage in maintaining mud quality. It acts as a critical barrier that ensures solids are effectively removed before the fluid is recirculated back into the well.

These shaker deck screens vibrate at high speeds, spreading the drilling mud evenly across the mesh surface. As the fluid passes through, solid particles like sand, silt, and rock fragments are captured and discharged. This allows the cleaned fluid to retain its properties and function efficiently in the wellbore, supporting lubrication, pressure control, and well stability.

Constructed from corrosion-resistant materials such as stainless steel mesh, polyurethane, or composite layers, rock shaker screens are built for durability and precision. Their performance directly impacts fluid recycling efficiency and the longevity of downstream equipment.

Beyond oil and gas, these screens are also used in non-petroleum applications. A shaker screen for dirt, for instance, is commonly used in construction, trenchless drilling, and soil remediation projects, demonstrating the screen’s versatility in handling solids separation across various industries.

Types of Rock Shaker Screens

Selecting the right rock shaker screen is essential for efficient solids control and depends on the drilling application, formation type, and shaker equipment used. Different screen designs and materials suit varied environments and operational needs.

Flat screens feature a simple, flat mesh surface and are usually more affordable and easier to install. However, their smaller surface area limits fluid handling capacity. In contrast, pyramid screens have a three-dimensional, undulating surface that increases the screening area by up to 125%. This design improves flow rates and enhances solids separation without increasing the screen’s footprint.

Steel frame shaker screens are durable and rigid, ideal for tough drilling conditions, but tend to be heavier and prone to corrosion. Alternatively, composite frame screens use lightweight, corrosion-resistant materials like fiberglass or plastic, offering improved shock absorption, especially useful in offshore rigs or high-vibration settings.

When it comes to installation, pretensioned screens come with mesh already stretched and bonded, ensuring consistent performance and quicker setup. Hook strip screens require manual tensioning and are generally more cost-effective for rigs that frequently change screens.

Beyond drilling, a shaker screen for dirt is commonly employed in construction and environmental projects, highlighting the versatility of these shaker deck screens in handling diverse solids separation needs.

How Rock Shaker Screens Work in the Drilling Cycle

During drilling, the drill bit breaks apart subsurface formations, creating rock fragments and cuttings. These cuttings are carried to the surface by the circulating drilling mud, which becomes contaminated with solids and requires treatment before reuse. This contaminated mud flows onto the shaker deck screen of the shale shaker unit, where the critical separation process begins.

The rock shaker screen vibrates rapidly, spreading the drilling fluid evenly across its mesh surface. As the mud passes through, solids larger than the mesh openings, such as rock fragments, sand, and dirt, are trapped and removed. The filtered fluid then recirculates back into the wellbore, preserving its rheological properties and ensuring efficient drilling operations.

If the shaker screen fails to remove fine cuttings adequately, the mud’s density increases, leading to higher hydraulic pressure. This can cause serious issues such as blowouts, borehole instability, or equipment damage. Using advanced rock shaker screens that effectively separate ultra-fine solids reduces the need for chemical additives and enhances fluid recovery.

Beyond oil and gas, shaker screens for dirt are also essential in construction and environmental drilling, where separating soil and debris from fluid is vital for efficient project execution.

Key Functions of Rock Shaker Screens in Drilling Optimization

Optimizing drilling performance goes beyond simply increasing speed; it requires efficient fluid management, prolonged equipment life, and effective cost control. The rock shaker screen plays a vital role in achieving these goals by ensuring clean drilling fluids and smooth operations.

- Improved Drilling Fluid Management

By effectively removing solids, the shaker deck screen prevents dilution and degradation of drilling mud. Keeping the mud clean reduces the need for chemical additives, extends mud life, and supports better control over wellbore conditions. - Extended Equipment Life

Clean fluid reduces abrasive wear on downstream solids control equipment such as desanders, centrifuges, and desilters. This results in lower maintenance costs and fewer unexpected shutdowns, enhancing overall rig reliability. - Cost Savings

Efficient screening minimizes mud loss and disposal volume, leading to decreased haul-off expenses and reduced consumption of fresh drilling fluids. - Enhanced Drilling Rate

A well-maintained mud system promotes a stable drilling environment, boosting the rate of penetration (ROP) and reducing non-productive time (NPT). Cleaner mud also enables more accurate pressure control and improved borehole stability.

Moreover, in non-oilfield operations, a shaker screen for dirt helps manage solids separation in construction and environmental projects, highlighting the versatility of these screens.

Properly selected and maintained rock shaker screens are essential to maximizing drilling efficiency and cost-effectiveness.

Common Applications Beyond Oil & Gas

Although rock shaker screens are most commonly recognized for their role in oilfield drilling, their utility extends across multiple industries requiring efficient solids separation.

In construction and trenchless drilling, shaker screens for dirt applications are vital for separating soil and debris from drilling fluids during pipe installation or tunneling operations. These screens help maintain fluid quality and prevent equipment clogging, ensuring smooth project progress.

Environmental remediation projects also rely on shaker screens to remove contaminated soil or sludge, allowing for safer disposal or treatment. This process is critical in cleaning polluted sites and protecting surrounding ecosystems.

Mining operations utilize rock shaker screens in ore separation and slurry dewatering, enhancing the efficiency of mineral recovery and reducing water usage. Similarly, in Horizontal Directional Drilling (HDD) and geothermal drilling, compact shaker units with effective shaker deck screens support fluid recycling and cuttings removal, optimizing operational performance.

These diverse applications highlight the versatility of shaker screens beyond traditional oilfield environments. Their ability to separate solids from fluids efficiently makes them indispensable across industries where fluid-solid separation is critical.

How to Choose the Right Rock Shaker Screen

Selecting the right rock shaker screen is essential to maximize both drilling performance and cost-effectiveness. Several important factors should be considered to ensure the screen meets your operational needs.

First, evaluate the API mesh size and conductance. API ratings define a screen’s ability to filter solids by size. Screens with higher mesh numbers capture finer particles but may reduce fluid flow, potentially impacting mud circulation. Choosing a screen with optimal conductance balances efficient solids removal with adequate fluid handling, ensuring cleaner drilling fluids and better wellbore stability.

Next, verify compatibility with the shaker deck screen system in use. Different shaker brands, including Derrick, M-I SWACO, and NOV Brandt, have unique screen dimensions and mounting configurations. Using a compatible screen avoids installation problems, vibration issues, and potential downtime.

Consider the drilling conditions, such as formation type, cuttings size, and depth. Coarse mesh screens perform better in gravel and rocky formations, while finer mesh is preferable in clay-rich environments. Additionally, a reliable shaker screen for dirt is critical for applications involving soil and debris separation in construction or environmental projects.

Finally, purchase from reputable suppliers who comply with API RP 13C standards. Certified vendors provide quality assurance, technical support, and consistent screen availability, ensuring smooth drilling operations under demanding conditions.

Maintenance Tips to Maximize Screen Life

Even the most durable rock shaker screen can fail prematurely without proper maintenance. Regular care and inspection are essential to extend the life of your screens and maintain efficient solids control.

Regular inspections are the first step. Before and after each use, check the screen for holes, torn mesh, or delamination. Damaged screens reduce separation efficiency and can allow solids to contaminate drilling fluids.

Cleaning the screens properly is also critical. Rinse with clean water or mild detergents to remove stubborn debris, especially after drilling through sticky or clay-heavy formations that can cause the shaker screen for dirt to clog. Avoid harsh chemicals that might degrade the mesh or frame materials.

Proper tensioning of the shaker deck screen is crucial. Loose screens vibrate unevenly, which increases the risk of tearing and reduces the screen’s ability to separate solids effectively. Make sure the screen is tightly and evenly secured on the shaker deck.

Finally, practice timely replacement. Screens showing excessive wear, decreased fluid flow, or signs of misalignment should be replaced promptly. Delaying screen changes compromises overall drilling efficiency and can lead to increased downtime.

Routine maintenance not only protects your investment but also ensures consistent drilling performance and reduces costly equipment failures.

Innovations and Future Trends in Shaker Screens

The field of solids control continues to advance, with new technologies reshaping how the rock shaker screen is designed and utilized. These innovations focus on improving efficiency, durability, and environmental sustainability.

One notable advancement is the development of self-cleaning mesh designs. These screens reduce blinding caused by sticky or clay-heavy formations, allowing for continuous operation without frequent cleaning interruptions. This feature is particularly beneficial when using a shaker screen for dirt in challenging soil or environmental drilling projects.

Another trend is the increased adoption of composite frames. These lightweight, corrosion-resistant frames not only extend the service life of shaker screens but also make handling and installation easier, especially in offshore or remote locations. The improved durability helps reduce downtime and maintenance costs.

Emerging smart screens with integrated sensors provide real-time monitoring of wear, vibration, and fluid throughput. Operators receive instant alerts about performance drops or potential failures, enabling proactive maintenance and reducing unexpected rig shutdowns.

Sustainability is also a growing priority. Manufacturers are exploring recyclable materials and reusable screen components to lower the environmental impact of drilling operations.

Together, these innovations enhance the performance of shaker deck screens, paving the way for more automated, efficient, and environmentally friendly drilling solutions in the future.

Conclusion

In the complex and high-stakes world of drilling operations, every component plays a critical role, and the rock shaker screen is no exception. As the first line of defense in the solids control system, it is essential for maintaining drilling fluid quality, protecting costly equipment, and enhancing overall drilling performance. Without an effective shaker screen, drilling fluid contamination can quickly lead to equipment wear, reduced drilling rates, and increased operational costs.

By gaining a thorough understanding of the various screen types, applications, and maintenance best practices, drilling professionals can make smarter choices that improve efficiency, reduce downtime, and maintain wellbore stability. Investing in high-quality and properly maintained shaker deck screens delivers measurable benefits not only in traditional oil and gas drilling but also across construction, environmental remediation, and other projects that require effective solids separation. For example, a reliable shaker screen for dirt is indispensable in construction and trenchless drilling operations, where efficient soil and debris removal ensures smooth progress and project success.

Ultimately, selecting the right screen is more than just an option; it is a necessity for achieving consistent, cost-effective drilling results in today’s demanding operational environments.