- How Liquid-Solid Separation Works in Real Mining Conditions

- Mining Dewatering Is a System Issue, Not Just an Equipment Choice

- Separation Best Practices That Actually Work on Mining Sites

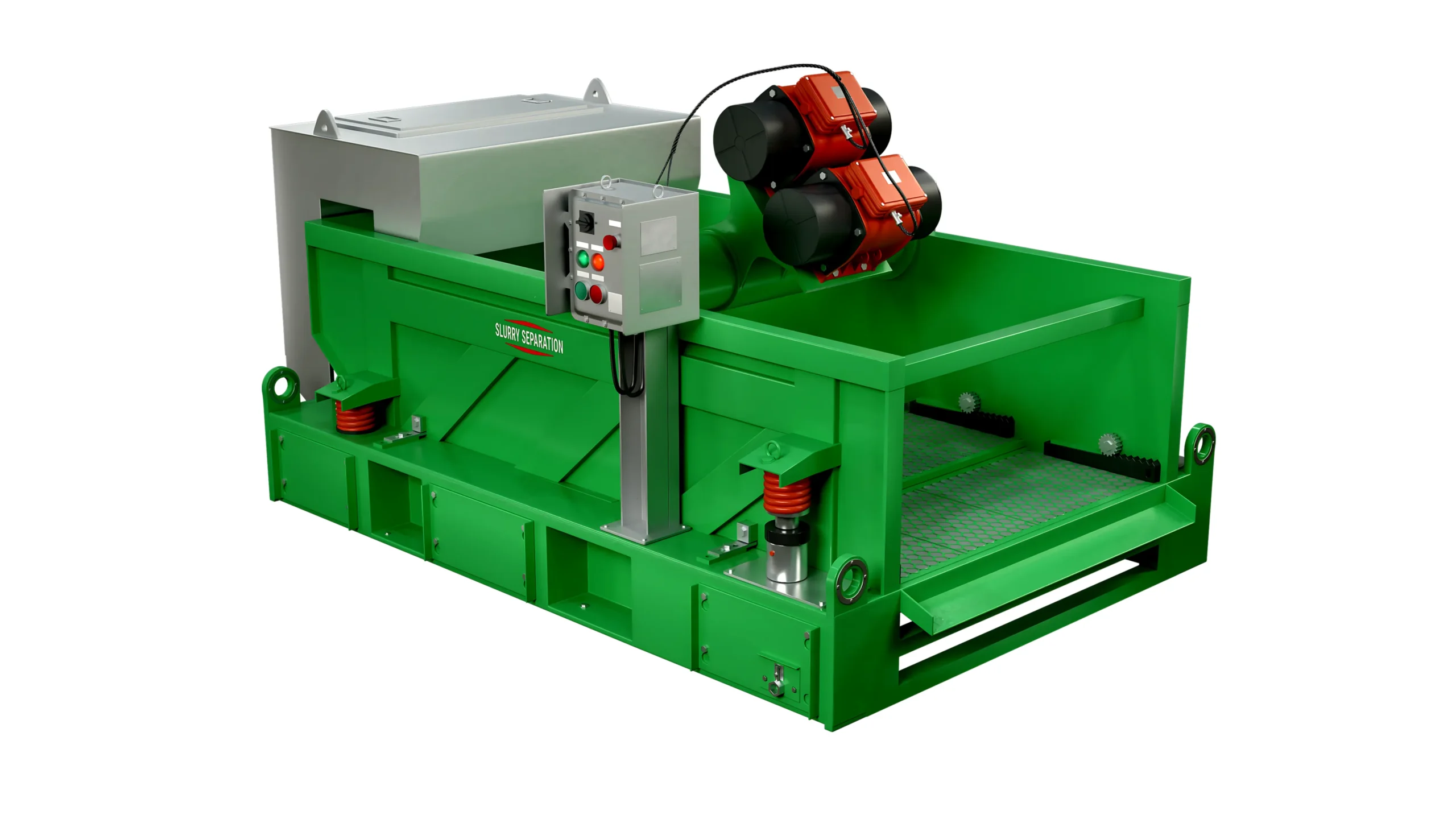

- How Slurry Separation Equipment Fits Into Mining Operations

- What Mining Operations Gain from Proper Liquid-Solid Separation

- Where Liquid-Solid Separation in Mining Is Heading

- Conclusion and Next Steps

In mining operations, separating solids from liquids is a daily reality, not a theoretical process. Slurry continuously moves through plants, tailings areas, and dewatering systems, and if liquid-solid separation is not handled properly, the impact is felt quickly. Excess water in solids, unstable tailings, pump wear, and water losses all point back to separation problems that were never fully addressed.

Today, liquid-solid separation plays a direct role in how efficiently a mine runs. It affects mining dewatering, water reuse, equipment reliability, and compliance with site and environmental requirements. As ore grades change and slurry characteristics vary, relying on basic or undersized separation setups often creates bottlenecks rather than solutions.

This is where practical separation best practices matter. Slurry Separation works with mining operations to apply liquid-solid separation systems designed for real-site conditions, not idealized ones. By focusing on consistent solids removal and effective dewatering, mining teams can improve process control, reduce water handling issues, and operate with greater confidence across the entire slurry circuit.

How Liquid-Solid Separation Works in Real Mining Conditions

In mining, slurry is never consistent. Particle size changes, solids concentration shifts, and flow rates vary across the day. This is why liquid-solid separation in mining cannot rely on theory alone. It has to work under changing conditions, with abrasive material and limited room for error.

At a basic level, liquid-solid separation removes free water from solids, enabling the material to be handled and processed. In mining dewatering systems, this usually happens through mechanical separation rather than chemical treatment. Screens, vibration, gravity, and controlled flow are used to allow liquid to pass while retaining solids.

The challenge is matching the separation method to the slurry. Fine particles behave differently from coarse material. High solids loads can overwhelm basic screens, while low-density slurry may pass through without proper separation. When systems are not sized or selected correctly, separation efficiency drops and dewatering performance suffers.

This is where separation best practices come in. Mining operations that focus on correct screen selection, proper feed control, and continuous solids removal see more stable results. Slurry Separation designs liquid-solid separation equipment that works within these real conditions. The focus is on handling variable slurry without constant adjustment, so mining dewatering remains reliable instead of reactive.

Mining Dewatering Is a System Issue, Not Just an Equipment Choice

In many mining operations, mining dewatering is treated as a separate task that starts once the slurry reaches the end of the process. In reality, dewatering performance is decided much earlier. If liquid and solid separation is weak at the front end, no dewatering unit can fully correct it later.

When excess water remains in solids, dewatering systems are forced to handle higher volumes than they were designed for. This leads to unstable discharge, inconsistent solids dryness, and frequent operator intervention. Over time, this also increases wear on pumps, conveyors, and disposal areas.

Effective liquid-solid separation reduces pressure across the system. By removing free liquid early, slurry volumes become more manageable and predictable. This allows dewatering equipment to operate within its intended range instead of being pushed to compensate for upstream issues.

Applying separation best practices means treating dewatering as part of a connected process. Slurry Separation works with mining operations to place liquid-solid separation equipment where it has the most impact, not just where space is available. When separation and dewatering are aligned, water recovery improves, solids handling becomes easier, and the overall process becomes more stable.

Separation Best Practices That Actually Work on Mining Sites

On mining sites, separation problems usually come from small decisions made early. Equipment is often selected based on capacity numbers, not on how the slurry actually behaves. Over time, this leads to poor liquid and solid separation and ongoing issues in mining dewatering.

One of the most important separation best practices is understanding the slurry before installing equipment. Particle size range, solids percentage, and abrasiveness all affect separation performance. When these factors are ignored, even well-built systems struggle to deliver consistent results.

Feed control is another area where problems start. Uncontrolled slurry flow overwhelms separation units, allowing solids to pass with the liquid. Stable feed rates improve liquid and solid separation and reduce stress on downstream dewatering systems. Simple adjustments at this stage often deliver better results than adding more equipment later.

Maintenance also plays a role. Worn screens, damaged seals, and improper setup reduce separation efficiency over time. Mining operations that inspect and maintain separation equipment regularly see fewer dewatering disruptions and more predictable solids handling.

Slurry Separation supports mining teams by applying these separation best practices during system selection and setup. Their approach focuses on practical performance under real operating conditions, helping mining dewatering systems work consistently instead of reactively.

How Slurry Separation Equipment Fits Into Mining Operations

On most mining sites, separation equipment has to work around existing layouts. Space is limited, slurry lines are already fixed, and downtime is expensive. Because of this, liquid-solid separation systems need to be practical to install and simple to run.

Slurry Separation equipment is typically placed where the slurry first becomes manageable, rather than at the end of the process. By removing free liquid early, the system reduces slurry volume before it reaches dewatering units or tailings areas. This improves overall mining dewatering performance without adding unnecessary complexity.

The focus is on continuous solids removal rather than batch processing. This helps maintain a steady flow and avoids sudden surges that can disrupt pumps and pipelines. In real mining conditions, this consistency is often more valuable than chasing maximum throughput numbers.

From an operational point of view, applying proven separation best practices through properly sized liquid-solid separation equipment allows sites to recover more water and handle solids more predictably. Slurry Separation works with mining teams to match equipment to actual slurry behaviour, helping operations stabilize separation performance and reduce water handling issues over time.

What Mining Operations Gain from Proper Liquid-Solid Separation

When liquid-solid separation is done properly, the benefits show up in daily operations, not just in performance reports. The most immediate change is better control over slurry. With less free water moving through the system, material flow becomes more stable and easier to manage.

For mining dewatering, this stability makes a clear difference. Dewatering units are no longer overloaded, discharge consistency improves, and operators spend less time correcting flow issues. Over time, this reduces wear on pumps, screens, and pipelines, thereby lowering maintenance effort and unplanned downtime.

Water recovery is another practical gain. Efficient separation allows more process water to be reused instead of discharged or replaced with a fresh supply. On sites where water availability is limited, this becomes a major operational advantage rather than an environmental checkbox.

Applying proven separation best practices also helps reduce risk. Stable solids handling lowers the chance of blockages, tailings instability, and unexpected shutdowns. Slurry Separation supports mining operations by delivering liquid-solid separation systems that prioritize reliability and consistency, helping sites operate with fewer interruptions and greater control over both solids and water.

Where Liquid-Solid Separation in Mining Is Heading

Mining operations are under increasing pressure to move more material while using less water. As a result, liquid-solid separation is becoming more closely integrated into overall process planning rather than treated as a standalone step. Sites are moving toward separation systems that can adapt to changing slurry conditions without constant manual adjustment.

One clear trend is placing separation equipment earlier in the slurry circuit to support mining dewatering before material reaches tailings or disposal areas. This reduces water volumes throughout the system and improves overall process stability. Another focus is on systems that can run continuously with minimal operator input, helping sites maintain consistency across shifts.

Applying proven separation best practices is also becoming more data-driven. Monitoring solids removal and water recovery helps operators identify problems before they affect production. Slurry Separation continues to support mining operations by providing liquid-solid separation solutions that fit into these evolving requirements, focusing on reliability rather than complexity.

Conclusion and Next Steps

Liquid-solid separation directly affects the efficiency of a mining operation. When separation is handled properly, mining dewatering becomes more predictable, water recovery improves, and solids handling issues are reduced. These outcomes come from applying practical separation best practices, not from adding unnecessary equipment.

Slurry Separation works with mining teams to design and implement liquid-solid separation systems that suit real site conditions. For operations seeking to improve dewatering performance, reduce water-handling challenges, or stabilize slurry management, reviewing the separation strategy is a practical starting point.