Dredging projects play a vital role in maintaining waterways, harbors, and coastal areas by removing sediment and debris. It also offers benefits

Slurry Separation Equipment Advances: Enhancing Dredging Efficiency

Dredging operations are crucial for various industries, including construction, mining, and environmental remediation. However, managing the resultant slurry is a significant challenge.

Civil Construction Challenges with Slurry Separators

Civil Construction Challenges with Slurry Separators Civil construction projects often involve excavation, drilling, and trenching activities that generate large volumes of drilling

Mud Separation: The Ultimate Guide

Mud separation is crucial in various industries, from construction to oil and gas. Understanding its significance and the techniques involved is essential

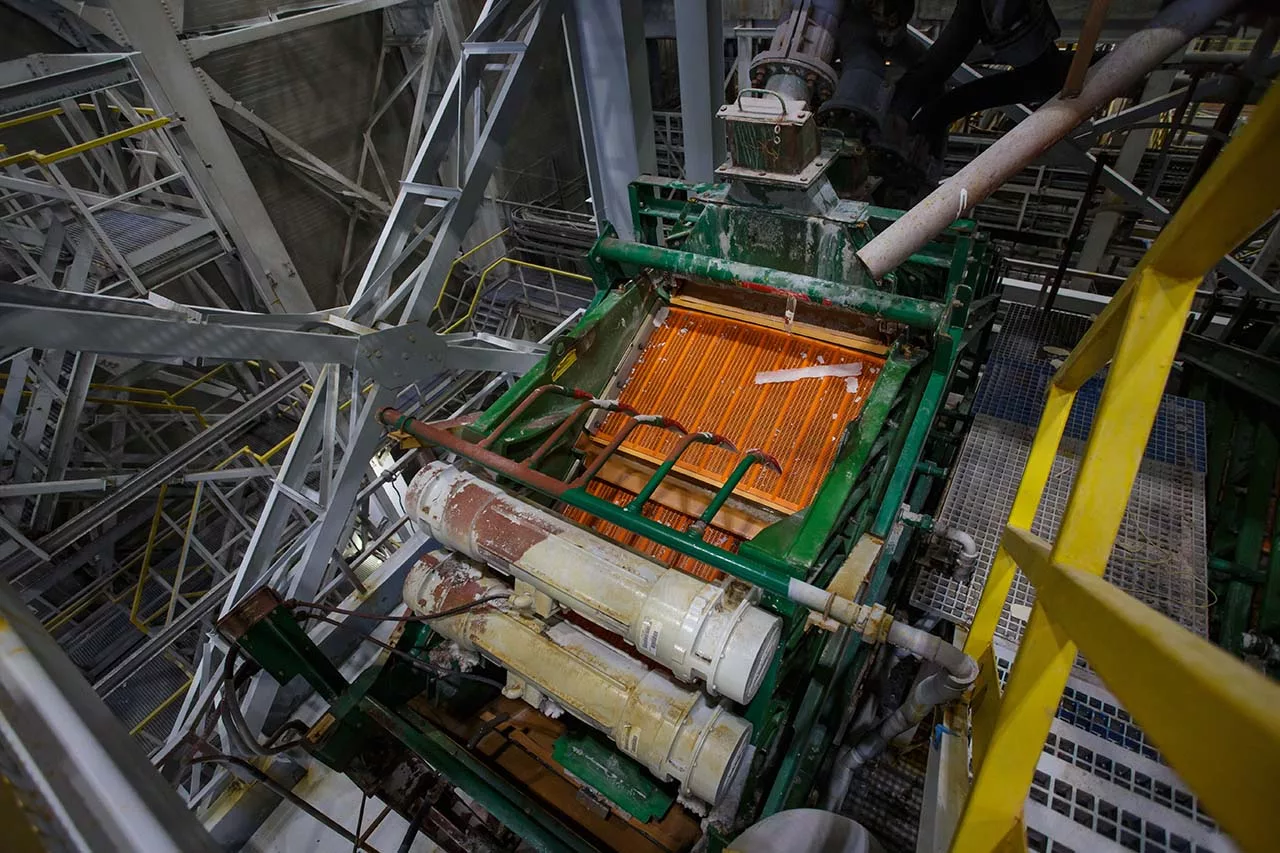

Top Box Vs. Weir Feeder in Slurry Separators

In solids control systems, choosing between a slurry separator with a top box loader and one with a weir feeder depends on

Oil and gas drilling operations pose various environmental concerns, including the release of drilling fluids, cuttings, and contaminants into the environment. These

Investing in a Slurry Separator: Five Critical Questions for Construction and Dredging Professionals

Investing in a slurry separator for construction or dredging projects requires careful consideration of various factors to ensure optimal performance, efficiency, and

The Role Of Slurry Separators In Dewatering

Dewatering operations play a critical role in various industries, including mining, construction, wastewater treatment, and environmental remediation, by separating water from solids

Screen Blinding: Strategies To Avoid It

Screen blinding is a common challenge in solids control operations involving slurry separators, where drilling fluid solids accumulate and obstruct the screening