Slurry Separators and Shale Shakers in Liquid/Solid Separation

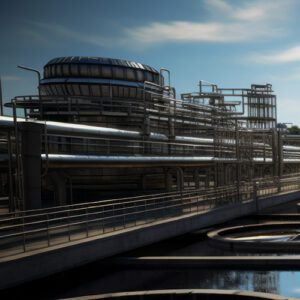

In liquid/solid separation applications, such as wastewater treatment, industrial processes, and mining operations, achieving efficient separation of solids from liquids is essential for maintaining process efficiency, product quality, and environmental compliance. Slurry separators and shale shakers are critical components in these applications, offering numerous benefits that optimize separation performance and enhance overall operations. Here we explore the key advantages of slurry separators and shale shakers in liquid/solid separation applications.

Improved Process Efficiency

Enhanced Product Quality

The use of slurry separators and shale shakers results in enhanced product quality by removing contaminants and impurities from the liquid phase. By achieving higher levels of separation efficiency, these technologies help meet product specifications and quality standards, ensuring that the final product meets regulatory requirements and customer expectations. Additionally, the removal of solids from the liquid stream reduces the risk of product contamination and improves the overall purity and integrity of the end product.

Reduction of Environmental Impact

Slurry separators and shale shakers are crucial in reducing the environmental impact of liquid/solid separation processes. By removing solids from liquid waste streams, these technologies minimize waste generation and pollutants, reducing the environmental burden associated with disposal and treatment. Additionally, recovering and reusing valuable resources from the separated solids contribute to resource conservation and sustainability, further mitigating environmental impact and promoting responsible waste management practices.

Protection of Equipment and Infrastructure

One of the primary benefits of slurry separators and shale shakers is their ability to protect downstream equipment and infrastructure from damage and wear caused by abrasive solids and debris. By removing solid particles from the liquid stream, these technologies prevent equipment fouling, erosion, and corrosion, extending the lifespan of pumps, valves, pipelines, and other process equipment. This results in reduced maintenance costs, decreased downtime, and improved reliability of equipment and infrastructure in liquid/solid separation applications.

Versatility and Adaptability

Slurry separators and shale shakers offer versatility and adaptability to various liquid/solid separation applications and operating conditions. These technologies can be customized to meet specific process requirements, particle size distributions, and throughput rates, ensuring optimal performance and efficiency across diverse applications. Additionally, modular design features and customizable configurations allow for easy integration into existing process systems, providing flexibility and scalability to accommodate changing production demands and processing needs.

Cost Savings and Return on Investment

The use of slurry separators and shale shakers results in significant cost savings and a favorable return on investment for liquid/solid separation applications. By improving process efficiency, reducing equipment maintenance, and minimizing downtime, these technologies help lower operational costs and enhance profitability. Additionally, the recovery and reuse of valuable resources from separated solids contribute to revenue generation and cost recovery, further enhancing the economic viability of liquid/solid separation processes.

The Benefits In Liquids/Solids Separation Are Clear

In conclusion, slurry separators and shale shakers offer numerous benefits in liquid/solid separation applications, including improved process efficiency, enhanced product quality, reduced environmental impact, protection of equipment and infrastructure, versatility and adaptability, and cost savings. These technologies are essential components of modern liquid/solid separation processes, enabling efficient removal of solids from liquid streams while maximizing productivity, minimizing environmental impact, and ensuring regulatory compliance.